Depending on the pipeline or the requirements, it may be necessary to mold the run into different shapes at certain points. In order to enable these outgrowths to attain a balance of pipelines’ structural soundness, a reinforcement pad would typically be put in the crucial areas of the connection joints. However, around the 80’s a novel idea came about which was known as Weldolet butt weld fittings which self-reinforces.

What a weldolet is?

A weldolet is a “single” fitting, it is a combination of a tee and a branched pipe, whose design shape matches the contour of the reformed run pipe and creates a strong and secure joint that is leak-proof and can withstand stress. Weldolets are commonly used for butt welded connections as it has been specifically designed to withstand high pressure and high temperature, making it a great fit for various industries.

Why do people in tribal areas prefer using weldolets in piping systems?

Self Reinforcement. Equally, to weld and mechanical lock, pressure ribs reinforce the surrounding frame in the weld area increasing the structural integrity of the fitting. This aims to restore the frame losses incurred when a hole is cut in a run pipe for a branch connection.

Enhanced Durability and Strength

Weldolet has a reliable construction, they provide stress concentration around branch junction, making them suitable for mission impossible applications in the oil and gas, petrochemicals and power industry.- The industry in which system collapse is not an option.

Also, No Worries About the Installation

Weldolets are simpler to fit than traditional enhancing techniques. Advanced technology brings the functionality into the design which in turn shortens the welding and more importantly fabrication and labor cost.

Dynamic

Weldolets work with all pipe dimensions and materials allowing for different combinations of piping layouts. There are multiple sizes and pressure ratings available to meet different needs in the industry.

Form and function There is More to Offering

Weldolets apply much less visual clutter than traditional framework branches connections which are reinforced with weld pads when they are installed. This is beneficial when the design and installation space is relatively small or where form follows closely with function.

Where Are Weldolets Used

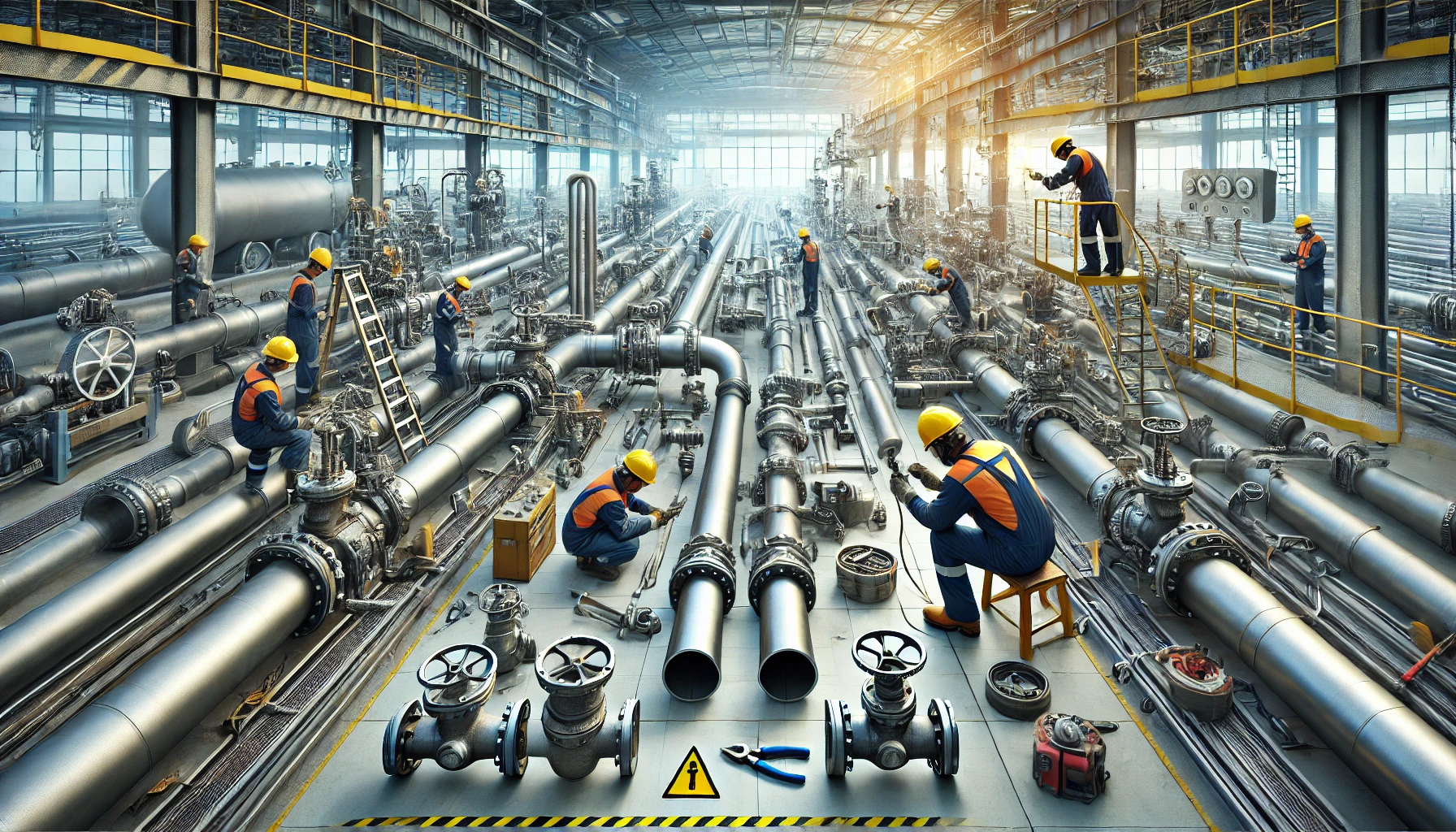

Weldolets are primarily used in most industries where there are structurally demanding and stress efficient connections. Some of these include:

Oil and Gas Pipelines: They are used in the transportation of crude oils, gases and other refined commodities at higher pressure.

Petrochemical Block Plants: Providing fitting branch connections in low and high temperature pipeline systems containing large varieties of chemicals.

Power Generation: Welded branch olets are most frequently used in steam and water lines where high pressures and temperatures are present.

Water Treatment Facilities: Such fittings are essential at the branch connections of fluid transport systems which are likely to be exposed to threatening conditions.

Other Types of Olets for Piping Systems

Weld-olets, together with thread-olets and sockolets belong to a family of components known as “olets” which are designed for particular cases in piping systems. Other popular types include:

Sockolet: For socket-weld branch connections.

Elbolet: For branch connections to elbows or bends.

Threadolet: This is used where threaded branches exist; it is very easy and quick to install them.

Branch olets are manufactured to meet the fabricating requirements, working pressures and operating conditions for different applications. This makes them economical throughout the industrial spectrum.

Conclusion

The welded type of olet is now a standard in modern piping systems as it has been found to be effective owing to its construction and design. With the extension of the worksheet in cut branches, it eliminates the use of support reinforcement pads which in turn makes implementation easier, and branch joints more durable. These olets also possess the ability to function under high-pressure and high-temperature conditions; thus, they are required in the oil and gas, petrochemical and power generation industries.

Induskart has the complete range of Weldolets and other branch fittings for different requirements of industrial piping systems. Whether it is the fittings for high-pressure pipelines fittings or the critical process plant systems, the solutions provided by us are guaranteed to be of high strength, safe, and conform to international standards.