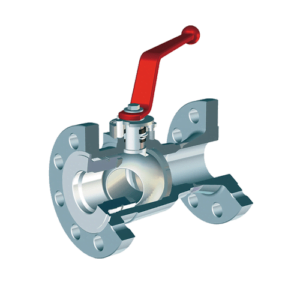

High-Performance Plug Valve for Industrial Fluid Management

The Plug Valve is one such versatile and dependable valves that is used extensively to control and manage fluid flow within different industrial sets. This plug valve design has been greatly appreciated for its robust design and effective performance. It is essential for all those industries requiring utmost precision in flow control, such as water treatment, chemical processing, and oil and gas. These [Flanged Plug Valve] and [Lubricated Plug Valve Manufacturers] design their plug valves for extreme durability and top-notch performance even in harsh conditions.

Material Specifications:

We make sure that we manufacture our Plug Valves by premium-quality stainless steel, cast iron, and special alloyed materials that assure durability and corrosion. Our [Xomox Lined Plug Valve] is equipped with a liner that affords it extra protection against harsh chemicals, ensuring superior application versatility. The materials have been selected to be sustainable within the environment and regulations.

Technical Specifications:

- Available in sizes ranging from 1/2 inch to 36 inches

- Pressure capabilities up to 1000 PSI

- Temperature range from -29°C to 260°C

Options include [Flanged Plug Valve], [Flowserve Plug Valve], and [Gas Plug Valve], each tailored for specific requirements and applications.

- These specifications ensure that our [plug valve] can stand up to a myriad of operational requirements, all the way from flexibility to reliability.

Standards and Compliance

We manufacture our plug valves to the highest standards, including ASTM, ISO 9001, and API. Being the top-notch plug valve manufacturers in India, we make sure that our products are tested to such standards of compliance, giving a reliable and safe solution to our buyers. These certificates speak of the quality and acceptance of our products worldwide.

Usage Instructions

Some maintenance practices that must be observed to ensure the best performance of the [Plug Valve] include:

- Regularly lubricate the valve to ensure smooth operation, especially those by lubricated plug valve manufacturers.

- Inspect the valve for wear occasionally and repair it to maintain its original integrity.

- Operate the valve as directed and avoid stressing to enjoy long life.

- For more detailed guidance, you can refer to the user’s manual or contact our support.

Applications

The [Plug Valve] finds application in an extensive range of industries due to its reputation of being consistent in the control of fluid flow.

- Chemical Processing: This valve is highly advantageous in the fluid processing that involves aggressive chemicals, lending great resistance to corrosion.

- Oil and Gas: [Gas Plug Valve] models include features designed for severe service in gas distribution systems where sealing tight and operation needs to be fast.

- Water Treatment: This valve is common equipment used in water treatment plants, which allows flow in the water to be controlled with minimum pressure.

- Pharmaceuticals: Plug valves are adequate for pharmaceuticals since cleanliness is kept at the maximum.

Features and Benefits

Features

- High Durability: We produce our plug valves from materials that can withstand abrasion and corrosion under tough operating conditions.

- Easy Maintenance: [Lubricated Plug Valve Manufacturers] products are designed to ease accessibility and lubrication to increase the service life of the valve.

- Versatile Design: The valve is available in various designs, including flanged plug valves and Flowserve plug valves, to meet all requirements of a given system.

Benefits:

- Efficiency: Plug valves have high flow coefficients that ensure good system efficiency in connection with low leakage.

- Safety: It is developed to assure operational reliability under high-pressure operation, creating safety for important applications.

- Cost-effective: Plug valves are competitively priced in relation to the quality of the product, so it’s a very safe investment for any operation.

Related Products

Enhance your valve system with these related products:

- [Butterfly Valves]: This type of valve is used for control and isolation in larger diameters.

- [Ball Valves]: Offer fast quarter-turn operation for on/off service.

- [Check Valves]: Prevents any backflow of fluid and therefore protects the integrity of the system.

Support and Warranty Information

All our [Plug Valves], including the [Flanged Plug Valve] and [Flowserve Plug Valve], come with some very good warranties and are backed by very strong backup services. We provide our customers with installation guidelines, an operational guide, and effective troubleshooting that will ensure that the best performance is achieved throughout the life of the valve.