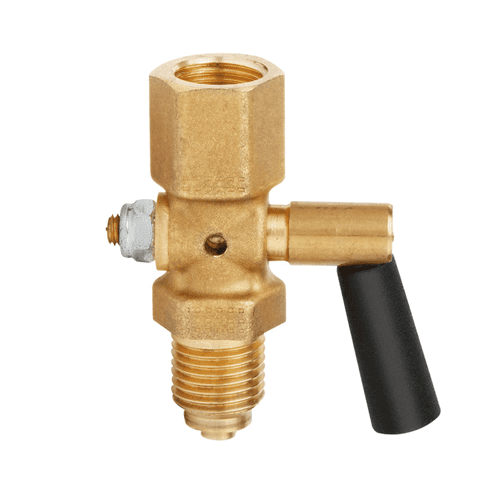

Precision Engineered Gauge Valve for Reliable Pressure Monitoring

A gauge valve, which is typically combined with a pressure gauge with a gauge cock, is necessary to observe and control the pressure of pipelines and tanks in many different sectors, such as oil & gas, water treatment, manufacturing, etc. It is appreciated for accurate reading while ensuring safety and efficiency of system operations. Moreover, this device comes with 3-way gauge cock for flexible connections and convenient system integration.

Material Specifications:

The materials used in making these valves are high-quality stainless steel or brass that have been hardened so as to improve their resistance against rusting or other forms of corrosion. The manufacturers also employ sustainable resources where applicable, thus conforming to environmentally friendly production practices without compromising on the quality standards expected from such industrial fittings.

Technical Specifications:

We offer several types of our gauge valves suitable for various working environments. We have sizes ranging between 1/4″ and 1″ that can withstand pressures up to 10000 psi when used as high pressure valves. The temperature range is -20°C to +250°C. Each model has accurate screw threads designed for seamless integration within pressure gauge-valve assemblies.

Standards and Conformity

The gauge valve satisfies crucial industry standards like ASTM and ISO 9001, thus ensuring quality manufacturing levels as well as reliability. Additionally, it has been certified to meet or even surpass all safety and quality benchmarks applicable, particularly in pressure-related applications, hence becoming an ideal choice for use within demanding industrial environments.

Instructions for Use

Frequent maintenance is required if you want your gauge valve to function optimally; this should include calibration checks, among other things, such as seal inspection procedures. Proper installation is vital, especially when you need accurate readings coupled with safety precautions taken during the entire process so it would be best done by professionals who are well versed in such matters. If there arise any common problems like leaks or pressure discrepancies, then please refer to the user’s manual, which contains comprehensive details about troubleshooting methods, but if need be, don’t hesitate to get in touch with our technical support team, who will be more than happy to help you out.

Applications

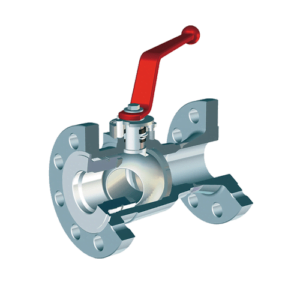

In systems where safe operation depends on monitoring and controlling fluid pressures, gauge valves become essential components. These are often used in combination with other devices designed specifically for real-time indication of pressure changes at critical points, like valves fitted with pressure gauges, among many others available out there today. You can always find them being utilized together with pressure gauge & valve assemblies mainly found in steam systems, HVAC systems, as well as process industries that require accurate control over steam/water pressures but not limited too. The Pressure Valve Gauge offers an integrated solution combining pressure relief with accurate monitoring, ideal for high-pressure applications.

Features and Benefits

Features:

Consists of a gauge cock valve that allows the gauge to be isolated easily for testing without shutting down the system.

Can be configured with a three-way gauge cock to enable versatile installation through multiple connection orientations.

Safety has been improved by integrating configurations of valve pressure gauges that prevent over-pressurization.

Built using gauge cock materials, which are durable enough to guarantee long-term reliability even under industrial conditions.

Benefits:

Enables the maintenance of system efficiency and safety through providing critical real-time data.

Simplifies system maintenance by combining pressure monitoring with relief functions in one device known as pressure valve gauge.

Meets industrial safety standards, thereby enhancing compliance and reducing risks associated with pressures accidents.

Operational visibility is increased by setting up valves with pressure gauges, thus allowing for immediate adjustments as well improving system responsiveness.

Related Items

These things will boost the performance and safety of your system:

Safety Relief Valves: These save you from excess pressure and are indispensable for the safety of your pressure vessel.

Flow Meters: These gauge the speed of fluid flow within pipelines, making them a good companion to the pressure gauge valve for a holistic system diagnosis.

Thermal Valves: These regulate the temperature and flow of fluids in systems that work under different temperatures.

These extra parts gel well with Gauge Valve to establish a firm control system while enhancing safety, thus enabling it to function best across diverse industrial setups.

Make sure you have the best pressure monitoring technology for your industry. If you need personalized attention. Our team of professionals is ready and waiting to help you achieve all your goals.

Support and Warranty Information

With Gauge Cock Valve and Valve Pressure Gauge included, our Gauge Valves offer full support and warranty. We have complete installation guides, continuous customers’ support, as well as guarantees for materials and manufacturing faults. Rely on us with top-notch norms of the industry coupled with our skilled workmanship in keeping your equipment functioning optimally.