High-Efficiency Dual Plate Check Valve for Industrial Fluid Control

A Check Valve is an essential device used in fluid control where it allows for the movement of fluids in one direction and then blocks it in another. Thus, a valve is fundamental to water treatment plants, chemical industries and hydraulic systems. This pilot-operated check valve has stood out because of its dependability as well as additional control features that make it fit for installation on complex hydraulic circuits demanding high-accuracy flow regulation.

Material Specifications:

They are built using various materials, including stainless steel, PVC, and cast iron, tailored to suit specific environmental and operational conditions. The PVC Check Valve is ideal for applications with low pressure and chemicals due to its lightweight and corrosion-resistance properties. The material selection is based on the lifecycle of the product and the necessity for environmental compliance.

Technical Specifications:

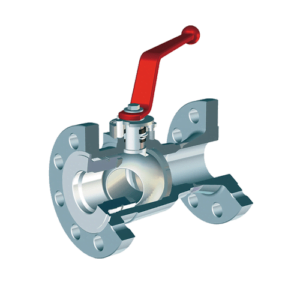

The sizes of these Check Valves range from 1/2 inches to 48 inches so as to suit the various pipeline sizes. The pressure rating can be as high as 600 PSI, while the temperature tolerances are between -10°C and 200°C. Types that may be found include [Wafer Check Valve], [Dual Plate Check Valve], and [Ball Check Valve], among others, depending on which is most appropriate for a specific utility in different operational contexts. Particularly, the reason why many people like it is its space-saving design.

Standards and Compliance

Every check valve is manufactured in conformance with ASTM, ISO 9001, and API. As one of the leading [check valve manufacturers] in India, we ensure that our products have been subjected to stringent testing procedures in regard to these standards, providing assurance to our clients regarding their safety, reliability, and performance. As a [Check Valve Supplier], it is also certified for adherence to quality management and excellence in customer service.

Usage Instructions

Routine preventive maintenance practices, including normal inspection and cleaning, will ensure the best performance of your Check Valve and a long lifetime. The proper installation of the check valve, as provided by [check valve manufacturers in India], does away with the most common problems of mispositioning and preserves good functional qualities. For troubleshooting and more detailed maintenance information, refer to the user manual or contact our technical support team.

Applications

The check valve, being one of the valves implemented with a one-way flow, is quite important. In applications like [Check Valve for Water Pump], this valve is highly implemented to avert backflow, which might end up impairing the pump. The hydraulic check valve type is of major importance within the hydraulic system as it is used for holding steady pressure and averting backflow of liquid under conditions of variable pressure.

Features and Benefits

Features:

- High pressures and rugged conditions can be withstood due to its rugged construction.

- Quick design ensures minimum flow of backwater.

- It is available in various types, for example, [dual plate check valves] and [pneumatic check valves].

Benefits:

- Ensures safety of the system and increases operational safety.

- This helps lower maintenance costs by preventing fluid contamination and reducing component wear.

- The prices are very competitive, really giving a good solution for the customer’s valve requirement with robust, reliable solutions.

Related Products

To complement your Check Valve installation, consider integrating:

- [Pressure Relief Valves]: Overpressure protection is a must.

- [Control Valves]: These valves have great precision over the flow and pressure within the system.

- [Strainers]: The latter can be placed inside so as to screen debris and prevent clogging of the check valve.

Support and Warranty Information

You can manage your plan, such as Our check valves, including the [Wafer Check Valve] and [PVC Check Valve], come with a full warranty and complete backup from our customer service. We can help with issues on installation, operation, and troubleshooting in order to make your valve perform perfectly during its service life.