| Operator: | Hand wheel operated |

| Body (MOC): | Bronze (Gun Metal) |

| End Connection: | Screwed End / Flanged End |

Bonnet Wheel Valve

Bonnet Wheel Valve: The cover for the opening sin the body is the bonnet, and it is the second most important boundary of a pressure valve. Like valve bodies, bonnets are in many designs and models available. A bonnet acts as a cover on the valve body, is cast or forged of the same material as the body. It is commonly connected to the body by a threaded, bolted, or welded joint. During manufacture of the valve, the internal components, such as stem, disk etc., are put into the body and then the bonnet is attached to hold all parts together inside.

Related Products

Gauge Cock

A gauge cock is a type of valve used primarily in conjunction with water level gauges to control the flow of fluids into the gauge. This valve allows operators to isolate the gauge from the vessel or pipeline system for maintenance or replacement without disrupting system operations. Gauge cocks are crucial in applications like boiler operations, where precise water level monitoring is essential for safety and efficiency. They typically feature a simple quarter-turn operation and provide a reliable means of sealing off the gauge from high pressures and temperatures.

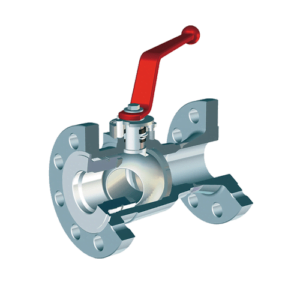

Ball Valve: Versatile and Reliable Flow Control Solution

A ball valve is a form of quarter-turn valve which uses a hollow, perforated, and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. Ball valves are durable, performing well after many cycles, and reliable, closing securely even after long periods of disuse. They are commonly used in applications ranging from residential to industrial for their robustness, ease of operation, and versatility in handling various fluids, gases, and slurries.

Air Release Valve: Essential Guide for Optimal System Performance

An air release valve is a crucial component in pipeline systems, particularly in water and wastewater pipelines, designed to automatically release trapped air and gas pockets to optimize system efficiency and prevent damage. This type of valve is essential for maintaining the flow and pressure stability within the system. Air release valves help prevent issues such as air lock, hydraulic inefficiency, and pipe bursts caused by high pressure due to trapped air. They are commonly installed at high points along a pipeline where air naturally accumulates. Their operation improves the energy efficiency of the system and reduces the risk of premature wear and tear on pipeline components.

Strainer Valve: Ensure Clean and Efficient Flow

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate, Parallel Slide, Pinch, Piston, Plug, Sluice, etc.

Strainer: Y-Strainers are devices for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

Mobrey Valve

Mobrey Valve: Mobrey is the name used for the Automatic water level controller, it comes under the category of mountings and fittings of Steam Boiler Assembly. As the name suggests, it is used for maintaining the water level in the Boiler shell. It is mostly used in smoke tube steam boilers not in water tube boilers, as the shell diameter of the former is greater than that of latter irrespective of their running capacities and working pressures.

Diaphragm Valve: Accurate and Leak-Proof Flow Control

A diaphragm valve is designed to control the flow of a substance through an enclosed space by the flexing of a diaphragm. It is commonly used in applications requiring precise flow regulation and sealing capabilities, particularly where the purity and cleanliness of the flow medium are essential. The valve’s design prevents any fluid from being trapped in the valve itself, making it ideal for use in the pharmaceutical, food and beverage, and biotech industries. This type of valve is also appreciated for its ability to handle corrosive fluids and slurries with relative ease.

Gas Valve

A gas valve is a critical component in managing the flow and pressure of gas in heating systems, appliances, and industrial processes. This type of valve is specifically designed to ensure safe and efficient operation when handling combustible gases such as natural gas or propane. Gas valves are equipped with safety mechanisms that shut off the gas flow automatically if the pilot light goes out or if a leak is detected, preventing potential hazards. They are commonly found in residential furnaces, gas-powered water heaters, and commercial gas stoves, playing a pivotal role in both safety and functionality.

Knife Edge Valve

A knife edge valve, more commonly known as a knife gate valve, is designed for on-off and throttling services, handling slurries, viscous, corrosive, and abrasive media. This type of valve features a sharp blade, which helps it cut through thick liquids and sludge with ease, making it highly effective in industries such as wastewater treatment, mining, and paper manufacturing. The knife gate valve’s design allows it to provide a tight seal even when dealing with fluids that contain solids, thereby preventing leaks and ensuring efficient flow control. Its ability to handle high-density fluids and its robust construction make it a preferred choice for challenging industrial applications.

Pressure Relief Valve: Reliable Pressure Control Solution

Pressure Reducing Valve: A relief valve or pressure relief valve is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire.

Ferrule Cock

Ferrule Cock: Ferrule Cocks incorporate a packed gland spindle and have a union outlet for connection to all ferrule bends or adaptors. RMC TPFNR Ferrules are for under pressure tapping. They incorporate a non-return gunmetal jumper valve and a high-density polyethylene tapered closing plug.

Needle Valve

Needle Valve: A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.

Sluice Valve: Reliable Flow Control for Your System

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate, Parallel Slide, Pinch, Piston, Plug, Sluice, etc.

Sluice Valve: A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened. The gate faces can be parallel but are most commonly wedge-shaped.

Safety Valve

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate, Parallel Slide, Pinch, Piston, Plug, Sluice, etc.

Safety Valve: A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve, which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits.

Steam Trap: Efficient Condensate Management Solution

Steam Trap: A steam trap is a device used to discharge condensates and non-condensable gases with a negligible consumption or loss of live steam. Most steam traps are nothing more than automatic valves. They open, close or modulate automatically.

Stop Valve: Reliable Control for Your System

Stop Valve: Stop valve is any sort of valve type that completely stops the flow of liquid flow through a pipe. Stop valves is mainly used in plumbing or industrial applications to shut off the flow of (hot or cold) water to a plumbing fixture, such as an icemaker, toilet, faucet, dishwasher etc.

Gate Valve: Precise Control for Flow Regulation

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate, Parallel Slide, Pinch, Piston, Plug, Sluice, etc.

Gate Valve: A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened. The gate faces can be parallel but are most commonly wedge-shaped.

Butterfly Valve: Efficient Flow Control Solution

Butterfly valves are very similar to ball valves they also work on the phenomenon of quarter-turn rotational movement which means by moving 90 degrees it could be either turned on to fully operated or turned off to restrict the flow of fluid. This is used to transfer, regulate or stop the movement of a fluid. They are used widely in the industries such as food processing, water supply industries, water pumping, etc. they are used wherein there is a need for a broad range of flow isolation Is required. “They belong from the quarter-turn family” and they usually have large pipe diameter.

Fusible Plug: Essential Safety Component for Your System

Fusible Plug: A fusible plug operates as a safety valve when dangerous temperatures, rather than dangerous pressures, are reached in a closed vessel. In steam engines the fusible plug is screwed into the crown sheet (the top plate) of the firebox, typically extending about an inch (25mm) into the water space above it.