Shopping cart is empty!

Induskart: Leading Valves Manufacturers and Authorized Dealer in Vadodara, Gujarat, India

Introduction

In the complex and demanding field of industrial valve manufacturing, Induskart stands as a beacon of excellence. As a leading Valves Manufacturers in India and an authorized dealer in esteemed brands like Leader Valves, Castle Valves, Prime Valves, Sir Valve, Aqua Valve, Wj-Neeta Valve, RMW Valve, PMW Valve, Trishul Valve and Strainer, and Newage, we offer unparalleled quality and variety. Our operations are backed by the registered trademark of Indusroof, further solidifying our reputation in the market.

Induskart’s Manufacturing Excellence

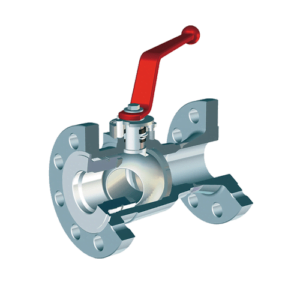

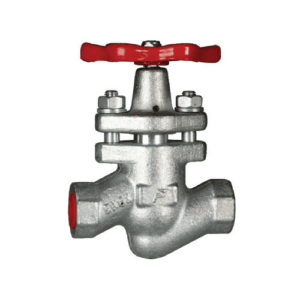

Induskart is not just another name in the industry; we are pioneers in valve manufacturing. Our state-of-the-art manufacturing facilities adhere to international standards such as API 600, API 6D, API 598 and ASME B16.34. We specialize in a range of valves, including but not limited to, ball valves, butterfly valves, gate valves, globe valves, breather valves, sluice valves and check valves, each designed to meet specific application requirements.

Strategic Partnerships with Leading Valves Manufacturers in India

Our excellence doesn’t stop at manufacturing. We have established strategic partnerships with leading Valve Manufacturers. As an authorized dealer for brands like Leader Valves, Castle Valves, Prime Valves, Sir Valve, Aqua Valve, Wj-Neeta Valves, RMW Valves, PMW Valves, Trishul Valves, and Newage, we offer a comprehensive range of valves that meet diverse industrial needs.

Distributor Alliances

In addition to manufacturing, Induskart has forged alliances with distributors of leading Valves Manufacturers, including distributors of L&T Valves, Audco Valves, Zoloto Valves, Weir-BDK Valves, Sant Valves, Neeta Valves, Mala Valves, Kirloskar Valves, KSB Valves and many more. This extensive network of distributors of top Valves Manufacturers in India allows us to provide a total solution for all your valve requirements.

Quality Assurance

Quality is the cornerstone of our operations. Our manufacturing processes are ISO 9001:2015 certified, ensuring that each valve meets or exceeds industry standards. Whether it’s pressure testing, material analysis, or dimensional checks, our quality control measures are exhaustive and in line with both Indian and international standards.

Benefits of Choosing Induskart as your Premier Valve Manufacturers

Customization: We offer bespoke solutions tailored to your specific operational needs.

Cost-Effectiveness: Our strategic partnerships with leading valves manufacturers in India and distributor alliances enable us to offer competitive pricing without compromising on quality.

Optimal Performance: Engineered to operate under varying pressure and temperature conditions, our valves meet the rigorous demands of diverse industrial applications.

Swift Order Fulfillment: Leveraging our expansive network of premier Valves Manufacturers, we are uniquely positioned to execute and deliver large-scale orders with exceptional efficiency and within a reduced timeframe.

High Durability: Our valves are designed for longevity, crafted from high grade materials and tested as per standard Indian and Internationa Standards.

Optimal Performance: Engineered to operate under varying pressure and temperature conditions, our valves meet the rigorous demands of diverse industrial applications.

Applications of Valves

Valves manufactured and distributed by Induskart find applications in a myriad of industries:

Petrochemicals: For controlling the flow of chemicals and other hazardous materials, ensuring safe and efficient operations.

Power Plants: Utilized in cooling systems, boilers, and turbines to regulate steam and fluid flow, contributing to optimal energy production.

Water Treatment: Essential for regulating water flow and pressure, ensuring a reliable and efficient water treatment process.

Pharmaceuticals: Employed in both sterile and non-sterile applications for precise fluid control, meeting stringent health and safety standards.

Marine Industry: Used in ballast systems, fuel systems, and other on-board applications, ensuring the vessel’s safety and operational efficiency.

Oil and Gas: Critical for the extraction, processing, and transportation of oil and gas, ensuring leak-proof and efficient systems.

Food and Beverage: Used in processing lines to maintain hygienic conditions and control the flow of liquids, ensuring product quality.

Chemical Processing: Vital for handling corrosive and reactive chemicals, ensuring safety and process efficiency.

HVAC Systems: Employed in heating, ventilation, and air conditioning systems for fluid and gas control, contributing to indoor comfort.

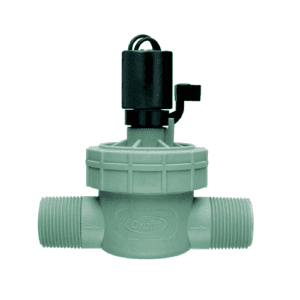

Agriculture: Used in irrigation systems to control water flow, ensuring efficient water usage for crop cultivation.

Mining: Essential for controlling the flow of liquids and gases in mining operations, ensuring safety and operational efficiency.

Automotive Industry: Used in various systems like cooling, lubrication, and fuel injection, contributing to vehicle performance and safety.

Pulp and Paper Industry: Employed in various stages of paper production for fluid control, ensuring quality and efficiency.

Textile Industry: Used in dyeing, treatment, and other processes, ensuring uniformity and quality in textile production.

Final Thoughts

Induskart is your go-to solution for high-quality valves, whether you’re looking for a reliable manufacturer or an authorized dealer. With adherence to international manufacturing standards and a commitment to quality, we are the preferred choice for industries across India, situated in Vadodara, Gujarat, India.

Looking beyond Valves? At Induskart, we also specialize in a vast range of Pipe Fittings. Seamlessly complementing our Valve offerings, our High quality Pipe Fittings ensure cohesive and efficient systems. Explore our Pipe Fittings Manufacturers in India to find the perfect solutions for your industrial requirements.

For valves that meet the highest industry standards and offer unparalleled performance, contact us today.

Email : info@induskart.co.in

Mobile : 9726429403, 9978796000, 9726419401, 9726419402