Valves

Induskart: Leading Valves Manufacturers and Authorized Dealer in Vadodara, Gujarat, India

Induskart's Mastery: Best Industrial Valve Manufacturer in India

Introduction

Induskart is one of the leaders in industrial valve manufacturing in India. We focus on a variety of valves such as ball valves, butterfly valves, gate valves, and many more making them the best-known manufacturer of high-quality valve products for diverse industries. As a leading Indian company involved in the manufacture of valves, we guarantee that our items are made according to international standards and with world-class technologies. In this regard, Induskart prides itself on being committed to delivering excellent products and services at all times through research and development. We continue striving to better our products as well as develop innovative solutions that can satisfy changing customer demands. Every single product that rolls off from our production line is of high quality due to the hard work put in by our dedicated team of qualified engineers and technicians.

Our Clients

Why Induskart?

When it comes to choosing an industrial valve manufacturer in India, Induskart is one of the most outstanding companies. Our dedication to quality and creativity in manufacturing valves has established us as a leading contender in this market. To meet the diverse requirements of different sectors, we offer several kinds of valves including ball valves, butterfly valves gate valves, and many others at Induskart. We produce high-quality valves that satisfy demanding specifications because we follow global standards and employ modern technologies.

- A broad range of products: Induskart’s wide product range includes various types of valves like Butterfly, Gate, and ball valves among others to accommodate industries with unique needs.

- Quality assurance: Our manufacturing operations are benchmarked against global standards to ensure our products conform to the highest possible quality benchmarks.

- Creativity and Technological advancement: Induskart uses highly developed technologies in its production lines resulting in continuous development of our products and services.

- Knowledge of Industry Standards: Over years in the sector, Induskart has gained a deep understanding of the industrial valve business thus making it a market leader.

- Customer First Policy: At Induskart, we offer customer-focused solutions that cater to specific industrial needs.

- International Application Compatibility – This is made possible by manufacturing products in accordance with worldwide standards as a result they can be used virtually everywhere on Earth for most applications.

Our Clients

Industries Served

Induskart’s industrial valves are vital in diverse industries such as:

- Petrochemicals: These ensure safe and efficient flow of chemicals and dangerous substances in petrochemical plants.

- Power Plants: They manage steam and fluid flows in cooling systems, boilers, and turbines to boost energy generation.

- Water Treatment: These play a key role in having water flow regulated at the correct pressure thus ensuring dependable water treatment processes.

- Pharmaceuticals: Such valves guarantee precise fluid control for sterile and non-sterile applications that have to meet strict health and safety standards.

- Oil and Gas: They are essential for leak-proofing oil extraction, refining, processing, storage, transportation systems, etc.

- Food & Beverage: Thus the valves enable hygienic conditions of production lines and regulate the movement of fluids through them to ensure high-quality products.

- Chemical Processing: They come into play when handling corrosive or reactive chemicals to make sure that it is done safely with optimal process efficiency.

- HVAC Systems: These ensure proper fluid or gas control applied in heating, air conditioning, and ventilation systems to provide comfort at home.

- Automotive Industry: In the same way they can control coolant flow or lubrication by other means and also they contribute towards performance optimization; fuel injection is another example where they are commonly used thereby enhancing auto safety features.

Our Products

Among the major industrial valve manufacturer, Induskart stands out because it supplies a wide range of valve types to meet different requirements. This includes high-performance butterfly valves, stainless steel ball valves, and floating ball valves among others. We have ISO and API certifications that make our products reliable and of good quality. Induskart specializes in automated valves that are efficient and easy to use. Gujarat-based Induskart is a dependable supplier for companies seeking industrial valves all over India. The growing demand for industrial valves has placed Induskart among the leading valve manufacturers in India. The trend in industrial valves is inclined towards us, which makes Induskart one of the top suppliers of such items countrywide.

Final Thoughts

Induskart is your go-to source for high-quality valves, serving as a reliable manufacturer and authorized dealer. Compliant with international manufacturing standards, our valves are the preferred choice across various industries in India. Located in Vadodara, Gujarat, we are dedicated to delivering valves that ensure performance and reliability.

For valves that meet the highest industry standards, contact us today.

Email: info@induskart.co.in

Mobile: 9726429403, 9978796000, 9726419401, 9726419402

Client Testimonials

Induskart's pipe fittings manufacturing in India delivers top-tier products, known for their reliability and precision, making them a trusted choice in the piping sector.

Brij Bhushan Bhardwaj

Induskart is where dreams are nurtured and turned into reality. The good mentor support and a cooperative team create an ideal atmosphere for personal growth. The supportive management encourages you to explore your potential and excel. I'm grateful to have built my career with Induskart and achieved my goals.

Kaivalya Nilkanth

Building my career with Induskart has been an incredible journey. The professional environment here fosters growth and learning. The mentor support is exceptional, and the management is genuinely supportive. The social culture adds a friendly touch, making every day enjoyable. Thanks to Induskart, I've achieved my career objectives.

Ruchi Khanvilkar

Dispatch Gallery

Air Release Valve: Essential Guide for Optimal System Performance

An air release valve is a crucial component in pipeline systems, particularly in water and wastewater pipelines, designed to automatically release trapped air and gas pockets to optimize system efficiency and prevent damage. This type of valve is...

Balancing Valve: Ultimate Guide to Choosing the Perfect One

Ball Valve: Versatile and Reliable Flow Control Solution

Blow Down Valve

Blow Off Valve

Blow Off Valve: A blow-off valve (BOV), dump valve or compressor bypass valve (CBV), is a pressure release system present in most turbocharged engines. Its main purpose is to take the load off the turbocharger when the throttle...

Bonnet Wheel Valve

Bonnet Wheel Valve: The cover for the opening sin the body is the bonnet, and it is the second most important boundary of a pressure valve. Like valve bodies, bonnets are in many designs and models available. A...

Breather Valve

Butterfly Valve: Efficient Flow Control Solution

Butterfly valves are very similar to ball valves they also work on the phenomenon of quarter-turn rotational movement which means by moving 90 degrees it could be either turned on to fully operated or turned off to restrict...

Check Valve: Reliable Backflow Prevention Solution

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate,...

Diaphragm Valve: Accurate and Leak-Proof Flow Control

Ferrule Cock

Ferrule Cock: Ferrule Cocks incorporate a packed gland spindle and have a union outlet for connection to all ferrule bends or adaptors. RMC TPFNR Ferrules are for under pressure tapping. They incorporate a non-return gunmetal jumper valve and...

Fire Hydrant Landing Valve: Reliable Fire Safety Solution

Float Valve: Automatic Water Level Control Solution

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate,...

Foot Valve: Reliable Suction Control for Pumps

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate,...

Fusible Plug: Essential Safety Component for Your System

Fusible Plug: A fusible plug operates as a safety valve when dangerous temperatures, rather than dangerous pressures, are reached in a closed vessel. In steam engines the fusible plug is screwed into the crown sheet (the top plate)...

Gas Valve

Gate Valve: Precise Control for Flow Regulation

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate,...

Gauge Cock

Globe Valve

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate,...

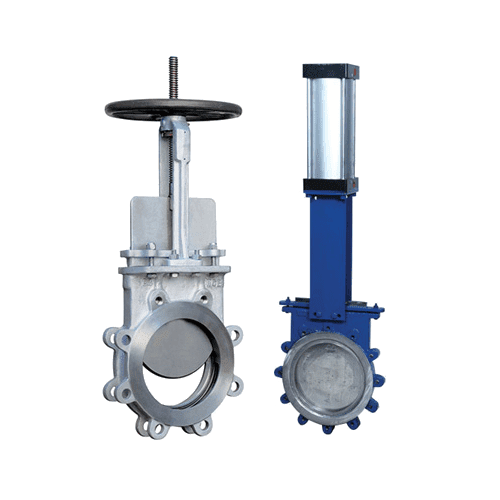

Knife Edge Valve

Mobrey Valve

Mobrey Valve: Mobrey is the name used for the Automatic water level controller, it comes under the category of mountings and fittings of Steam Boiler Assembly. As the name suggests, it is used for maintaining the water level...

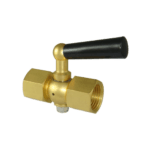

Needle Valve

Needle Valve: A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.

...Non Return Valve

Piston Valve

Piston Valve: A piston valve is a device used to control the motion of a fluid along a tube or pipe by means of the linear motion of a piston within a chamber or cylinder. Examples of piston...

Plug Valve: Durable Flow Control Solution

Plug Valve: Plug valves are valves with cylindrical or conically tapered “plugs” which can be rotated inside the valve body to control flow through the valve. The plugs in plug valves have one or more hollow passageways going...

Pressure Relief Valve: Reliable Pressure Control Solution

Pressure Reducing Valve: A relief valve or pressure relief valve is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or...

Reflux Valve

Reflux Valve: A check valve, clack valve, non-return valve, reflux valve, retention valve or one-way valve is a valve that normally allows fluid to flow through it in only one direction. Check valves are two-port valves, meaning they...

Relief Valve: Trusted Solution for Pressure Management

Relief Valve: A relief valve or pressure relief valve is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or...

Safety Valve

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate,...

Sight Glass Valve

Sight Glass Valve: A sight glass is a transparent tube through which the operator of a tank or boiler can observe the level of liquid contained within. Simple sight glasses may be just a plastic or glass tube...

Sluice Valve: Reliable Flow Control for Your System

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate,...

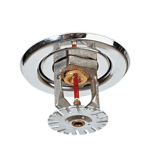

Sprinkler Valve: Optimal Water Flow Control Solution

Sprinkler: A sprinkler is a device used to spray water. Sprinklers are used to water plants or grass, or to put out fires in buildings. a device perforated with small holes that is attached to a garden hose...

Steam Trap: Efficient Condensate Management Solution

Steam Trap: A steam trap is a device used to discharge condensates and non-condensable gases with a negligible consumption or loss of live steam. Most steam traps are nothing more than automatic valves. They open, close or modulate...

Stop Valve: Reliable Control for Your System

Stop Valve: Stop valve is any sort of valve type that completely stops the flow of liquid flow through a pipe. Stop valves is mainly used in plumbing or industrial applications to shut off the flow of (hot...

Strainer Valve: Ensure Clean and Efficient Flow

Valve: Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly, Check, Diaphragm, Gate, Globe, Knife Gate,...

Air Release Valve : Venting is the process of releasing trapped air from the pipe system to improve its performance. Air vents or air release valves are commonly used for this purpose. It is called venting when air is removed from a system during the commissioning or after maintenance. To maintain the effectiveness and efficiency of a pipeline, one must get rid of the entrapped air from it. Operating problems in a pipe system can be a result of having pockets of air which lead to decreased flow rate, increased pressure drop and corrosion. The use of open ends to release these pockets permits an optimal performance for any given system.

Balancing Valve: Hydronic systems must have balancing valves for accurate distribution of water flow rates amongst multiple coils. The hydronic systems’ flow distribution helps in realization of high performance and efficient operation. Properly designed pipelines help in distributing hot water or steam evenly throughout the building preventing overheating or underheating particular areas thus maintaining comfortable indoor conditions. One such critical component necessary for correct flow distribution within hydronic systems is the balancing valve.

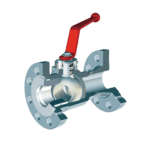

Ball Valve: This valve is versatile and can be used in many applications as it has simple operations that only require quarter-turn movement of the lever handle or wheel to open/close these valves making it suitable for different environments and industries.

One of the key benefits of a ball valve is its ability to provide tight shut-off and control of flow. The design of the valve features a spherical ball with a hole through the center, which allows for complete sealing when the valve is closed. This makes it a popular choice for applications where leakage prevention is critical, such as in the petrochemical, pharmaceutical, and food and beverage industries.

Butterfly Valve:The water treatment industry is one of the places where they are commonly used. The butterfly valve’s disc is positioned on the shaft and it can be turned to control the fluid or gas flow across the valve. When fully open, it permits maximum capacity while when closed, completely obstructs it.

Butterfly valves are popular for their speed and easy maintenance. Again, they are small in size and light compared to other types of valves hence suitable for space-limited cases. Further, butterfly valves have a lower pressure drop than any other type of valve; thus they consume less energy.

Check Valve:A check valve is a kind of valve that allows the passage of fluid or gas in one direction only. Responding to changes in pressure within the system, this device opens and closes on its own thereby keeping off reverse flow and ensuring that the flow of fluid or gas is constant in the intended path.

In addition to that, they are also used throughout many other industries such as water supply systems, heating and cooling installations, oil and gas pipelines, and many more industrial processes. They help protect equipment from damage, maintain efficiency within the system, and ensure safety and reliability for all systems involved.

Fire Hydrant Landing Valve:A key to fighting fire is the rapid availability of water in emergency situations. Fire hydrant valve keys are essential implements that firefighters employ for quickly obtaining water from fire hydrants during crises. These keys have been designed in a manner that allows them to fit the unique shape and size of fire hydrant valves so that it can be easily opened or closed by a firefighter wishing to get water for firefighting purposes.

When there is a fire outbreak, having a fire hydrant valve key can make sure that firefighters easily acquire the water they need to extinguish the flames thereby preventing further damage. These keys are usually manufactured using materials like steel and aluminum that are tough enough to endure conditions firefighters face while at work ensuring reliability when it matters most.

Float Valve :Automatically regulates liquid levels in order to maintain the desired level. Float valves are mechanical devices typically used for water tanks, reservoirs, and other liquid-containing systems in order to regulate automatically the level of liquids. A float valve is made up of a float which is a buoyant object that goes up or down with the level of liquid connected with a valve mechanism.

When the liquid inside the tank rises above the required level, the float also rises hence closing off the valve and stopping further inflow of more fluid into the tank. Conversely, when the liquid falls below a certain predefined point, it leads to a lowering of the float opening up more space for additional fluids into the tank.

Foot Valve :It is designed to allow flow in one direction only and prevent reverse flow. This will help maintain a steady flow of liquid within the system while avoiding backflow that could damage equipment or disrupt processes. Usually, foot valves are placed at the inlet of a pump or other equipment to ensure that the fluid being pumped moves only in the intended direction. For instance, they are commonly used in irrigation systems, municipal water supply systems, and other applications where prevention of backflow is vital.

Gate Valve :This controls flow through a gate that can be raised or lowered so as to allow full flow or no flow at all. Gate valves are common in industries like oil and gas, water treatment, power generation, and chemical processing. They also provide an excellent seal when fully closed hence suitable for use where there might be leakages.

The gate in a gate valve is typically made of metal and is raised and lowered within the valve body to control the flow of fluid. When the gate is raised, it allows for full flow, and when it is lowered, it blocks flow completely. This on/off functionality makes gate valves suitable for applications where precise flow control is required.

Globe Valve: It is best for them to use these mechanisms in fluid flow control devices which can be moved up and down or side to side, known as discs or gates. This makes them ideal for applications in which flow control is important because this design allows for more accurate adjustment of flow rates compared with other types of valves.

One of the most common applications of globe valves is found in HVAC systems, where they are employed to regulate the movement of water or steam through pipes so as to manage the temperature inside a building. This is also true across industries including chemical processing and petrochemical plants where precise control over flow rates is essential to ensure safe and efficient operation.

Knife Edge Valve :The knife edge valve is designed for use in areas where sealing and precision control are required. It falls under the control valves category, which has a sharp-edged disc as a seal element. This design prevents any leakage by ensuring that the valve is well-sealed when closed. In addition, it is possible to make very accurate flow control using the knife-edge disc, which makes it perfect for installations that require precise flow regulation.

Non-Return Valve :This ensures that fluid flows in a single direction, thus avoiding backflow and hence protecting the system. It is also used in industries like oil and gas, water treatment, and chemical processing to prevent contamination as well as damage to equipment. Non-return valves are also installed on other common devices like pumps, compressors, plumbing systems, etc., to ensure flow efficiency is maintained and accidents are avoided.

Piston Valve: Is suitable for demanding applications with high flow capacities but requires tight shut-off. The flow passage in a piston valve is regulated by a piston within the valve body. Upward and downward movement of the piston while inside the valve body opens or closes the flow passage respectively. In particular, this design shows a large capacity for handling fluids under extreme demands where large quantities of fluids require control.

One of its key merits lies in being a shut-off valve that can seal tightly. Specifically, when closed, the piston makes contact with the valve’s body preventing any fluid loss or leaks from occurring. This is particularly critical where precise control is required or where hazardous or expensive substances are being managed.

Plug Valve: Various fluid handling systems can be switched off simply and effectively. It is a valve type that offers simple and effective shut-off control for various fluid handling systems. The plug valve contains a cylindrical body with a tapered or cylindrical plug which can be turned around inside the body to regulate the flow of liquid in it. When the plug is rotated perpendicular to the flow direction, the valve is closed thereby blocking fluid from flowing through it. When the plug is rotated parallel to the flow direction, the valve is opened, and as such fluids are able to move through it.

These types of valves are commonly used in industries like oil and gas, water treatment, and chemical processing where reliable shut-off control is a must. They are often used when applications require complete flow shutoff or transition from on to off rapidly since their basic construction allows for quick actuation.

Pressure Reducing Valve: This is very necessary for system protection because it keeps the downstream pressure constant. To avoid damage to the system, this is a must-have element in any fluid system since it will ensure high-performance levels.

The pressure-reducing valve acts by balancing fluid flow rates to keep downstream pressure at a uniform level even if upstream pressure fluctuates. It also aids in averting overpressure situations that can result in system breakdowns through leaking, bursting, or other mechanism as well as preventing equipment and components within the system from experiencing pressures exceeding their design limits.

Reflux Valve: The backflow controller is employed in order to prevent the sensitive electronics from getting destroyed. The reflux valve, sometimes known as the check valve, is specifically meant to deal with the problem of backflow within a system. It is mainly used for preventing flow reversal within a pipe or plumbing system which can be extremely harmful to delicate types of equipment and machines that are in place.

The reflux valve operates by letting fluid go in one direction only but stopping it from flowing back in oppositely. This helps to maintain consistent liquid flow throughout the system and safeguard against potential damages resulting from backward flow.

Safety Valve : This opens a pressure relief valve to discharge the excess pressure and protect equipment. Examples of systems and processes that require safety valves for pressure control are many. These types of valves are capable of opening automatically in case the pressure crosses a predetermined threshold, thus allowing the release of excess pressure and avoiding any prospect of overpressurization.

The main aim behind constructing a safety valve is to save equipment such as boilers, pipelines, pressure vessels, or any other system from being exposed to high pressures. Safety valves relieve excessive pressures hence preventing catastrophic failures, explosions, and hazardous accidents due to extreme conditions created by a large mass of compressed gas.

Sight Glass Valve: To monitor and maintain fluid flow, it permits visual monitoring for maintenance purposes. It is typically made of see-through materials like glass or plastics that allow the operator to see what the inside of the piping system looks like so that they can make sure that fluids are flowing well and look out for any problems such as air bubbles or sediments. Some industries particularly in chemical processing, food & beverage, and pharmaceuticals, require constant fluid flow to enhance safety standards and control quality.

Sluice Valve: A sturdy valve meant for controlling water flow by opening or closing it. Sluice valves, also recognized as gate valves, are crucial elements of the water system and are used to govern the flow of water. They are usually made out of strong materials like cast iron or stainless steel in order to endure high pressure and continuous usage. The sluice valve design includes a flat gate that slides up and down between two seats in order to permit or stop the passage of water.

Strainer Valve : To protect the downstream components, it removes debris and particles from a fluid. For various fluid systems, strainer valves are crucial components whose role is to ensure that equipment functions properly thus avoiding damage to other downstream elements. These valves are designed in such a way that they filter out dirt and impurities in the fluid as it moves through the system like removing dirt or any other contaminants which can easily clog or damage delicate machines.

A strainer valve can be used to prevent blockages and save your time, and cost of replacing parts by keeping them clean and unblocked so that they can run smoothly with no complications. These valves are particularly useful in systems dealing with liquids or gases like water treatment plants, chemical processing factories, and HVAC systems.

Apply Now

- Menu

My Cart

Shopping cart is empty!