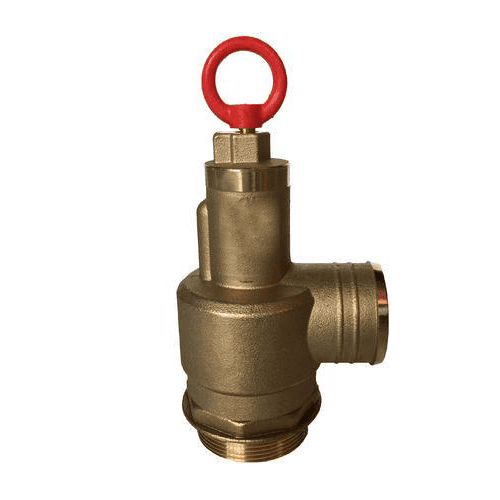

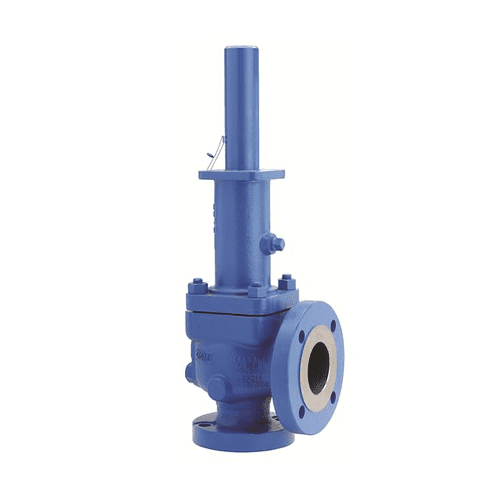

High-Safety Relief Valve for Critical Pressure Control

The Relief Valve is a specially designed important safety valve that protects the pressure vessels and piping systems by relieving them with excess pressure. These are called for in different industrial service applications, including chemical processing, oil and gas, water treatment, and others, to lessen the potential for catastrophe due to the failure of a [Relief Valve]. Among the line of brands for [Pilot Operated Relief Valve], it is reputed for being sensitive and having the best accuracy in a critical situation.

Material Specifications:

Our safety relief valves, being manufactured from robust materials such as stainless steel, brass, and special alloys, endure harsh working conditions and serve for a long duration. The materials used by [ Safety Relief Valve Manufacturer] are with the highest quality and sustainability, in respect to the environment, without compromising on either safety or performance.

Technical Specifications:

- Sizes ranging from 1/4 inch to 24 inches

- Pressure capabilities from 50 psi to 6000 psi

- Temperature ratings from -196°C to 600°C

- Types include [Hydraulic Relief Valve], [Thermal Relief Valve Manufacturer], and [Vacuum Relief Valve Manufacturer], each designed to meet specific operational demands.

- Those specifications make the [Relief Valve] applicable to a wide range of applications and maintain its flexibility and reliability.

Standards and Compliance

Our Relief Valves are designed following important standards including ASTM, ISO, and API among others. Being a leading manufacturer of Relief Valves, we have conducted numerous tests to ensure that every valve conforms to international safety and quality standards. Compliance ensures customer confidence and product reliability in the most sensitive and hazardous environments.

Usage Instructions

To ensure proper and reliable operation of your [Relief Valve], the following shall be adhered to:

- Periodically test the valve to ensure that it operates at the correct set pressure.

- Schedule regular maintenance to identify corrosion or blockages that prevent the valve from operating properly.

- Replace the valve according to manufacturer’s recommendation or if deformed or visibly damaged.

- For detailed operation procedure, refer to the user manual, or call [Safety Relief Valve Manufacturer] for professional support.

Applications

The [Relief Valve] finds wide application on account of its safety and protective functions:

- Power Generation: Applied in boilers and reactors where the pressure can reach critical levels. The [Safety Relief Valve] will work to protect the boiler from overpressurization, ensuring the integrity of the operation and the plant’s safety.

- Oil and Gas: [Pilot Operated Relief Valve] models are used to control surges in pressure within pipelines and storage facilities caused by processing or temperature variations.

- Chemical Manufacturing: Manufacturing of [Thermal Relief Valves] used to relieve thermal expansion pressures in the reaction vessels.

- Water Heating Systems: This is the manufacturer for the residential and commercial water heater relief valves, providing protection against high pressure and temperatures.

Features and Benefits

Features

- Rapid Pressure Discharge: Permits the rapid and efficient release to prevent damage and ensure staff and equipment safety.

- High Customizability: Available in a range of sizes and materials, even including specialty offerings like the [ Vacuum Relief Valve Manufacturer ] for your unique industry needs.

- Durability: Designed for the toughest circumstances, working for the long haul with the capacity for high performance.

Benefits:

- Prevents System Failure: They remove excess pressure instantly and thus prevent the possibility of future breakdown or even catastrophic failure.

- Enhances System Efficiency: When the operating pressure is adequately maintained within the recommended ranges, the overall system efficiency and performance increase.

- Regulatory Compliance: This implies that its safety standards must be high and in compliance with national and international regulatory requirements.

Related Products

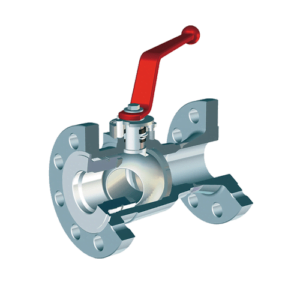

To fully protect your system, consider integrating these related products:

- [Pressure Reducing Valve]: Reduces incoming pressure to safer, more manageable levels for various applications.

- [Check Valves]: Allow the medium to pass through in one direction only, therefore keeping the integrity of the system.

- [Hydraulic Relief Valve]: A hydraulic system designed to relieve possible pressure rises of rapid increases that can be experienced.

Support and Warranty Information

All our regulators, with and without safety shut-off, have complete customer support and service support, through extended warranty agreements. This includes detailed installation guides, operational support, and troubleshooting services which will help keep your equipment up and running safely and efficiently.