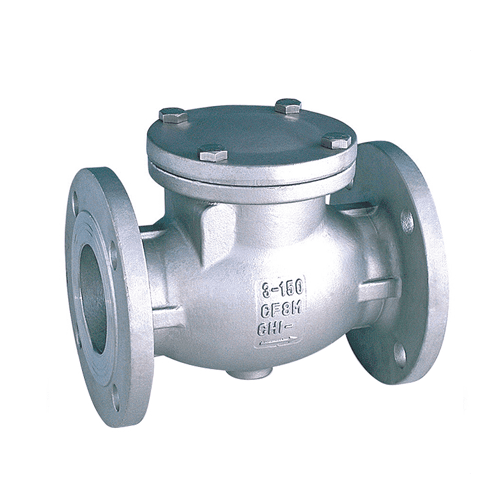

Robust Dual Plate Non-Return Valve for Industrial and Applications

The check valve, or Non-Return valve, is designed to prevent the fluid flowing from going back into the pipes. It serves as an integral component of the water pumps, especially those systems where there is potential backflow that might lead to pump damage. The Dual Plate Non-Return Valve has a smaller design with a superior sealing capacity. This makes it suitable for applications requiring narrow spaces or flows.

Material Specifications:

They are designed using materials that would endure for long periods for them, considering stainless steel and PVC as usable materials. All the materials chosen are non-corroding and eco-friendly, so they comply with the latest sustainability standards.

Technical Specifications:

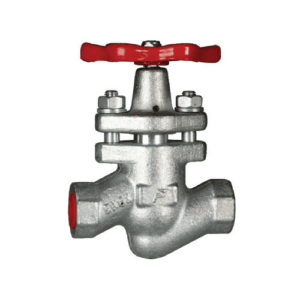

We offer different sizes of our Non-Return valves, including wafer-type NRV Valve and pilot-operated non-return valves, among others so that they can fit any system requirement. They can withstand pressures of up to 420 bars as well as temperatures ranging from -196°C to 600°C, thereby making them suitable for use under different operational environments. Swing, lift, and dual plate models are some types of NRV valves available, each optimized for specific flow dynamics.

Standards and Compliance

The non-return valve conforms with international standards such as ASTM, API, and ISO 9001. All valves are tested stringently against these standards to ensure that they perform at their best and remain reliable. Our credentials as a non-return valve manufacturer and non-return valve supplier show our dedication towards quality and customer satisfaction, which builds confidence in the industry acceptance and safety of our products.

Usage Instructions

Regular maintenance is essential to ensure that this equipment functions optimally as a non-return valve over an extended period. This maintenance should include frequent inspections for wear and tear as well as the removal of dirt particles, especially in critical applications where it is used as a non-return valve for a water pump. A common issue that can impair valve operation is improper installation, often due to incorrect positioning. It is crucial to follow the manufacturer’s instructions carefully during installation. If you encounter any problems or need assistance with maintenance, please refer to the detailed manual provided or contact our professional team for support.

Applications

The non-return valve is also referred to as the NRV valve and the non-return check valve in some specialized versions. This valve is needed by systems that only allow flow in one direction to prevent backflow that can cause failure or endanger life. They are used in plumbing systems, water treatment plants, and heavy industries where backflows may lead to serious operational problems. Moreover, there exists an optimization of the NRV Non-Return Valve type for situations with fast response to changes in the direction of flow.

Features and Benefits

Features:

The strong design of a non-return valve enables it to be fitted horizontally or vertically in different pipe systems.

It incorporates functions of the check valve and non-return valve that prevent backflow automatically to improve the safety and efficiency of the system.

There are varieties of NRV types, such as swing, lift, and tilting discs, that can be used based on different operational requirements and flow characteristics.

The Dual Plate Non Return Valve is efficient in terms of space utilization, especially when dealing with large-diameter pipes, thus reducing the pressure drop across the valve.

Benefits

Safeguards pumps and compressors against water hammer as well as back pressure.

It ensures that there are minimal operational disruptions, thus improving the reliability of the whole system.

Low maintenance requirements and cost-effective NRV valve prices contribute to a cheaper total cost of ownership.

By preventing reverse flow incidents, this valve helps systems comply with safety and environmental regulations, thereby reducing the risk of environmental damage. It ensures that potentially hazardous fluids do not backflow into the clean water supply or the environment, which could lead to contamination and regulatory violations.

Other products

Below are some related items that can be used alongside each other to realize complete protection against backflows:

Pressure relief valves: These should be fitted where there is a likelihood of excess pressure building up to allow for safe venting without causing any harm.

Butterfly valves: They offer an efficient way of controlling flow rates which may be used together with non-return functionalities to enhance control capabilities further.

Water filters: They help in purifying the contents of a system while also safeguarding against sediments or debris clogging up non-return valves, thereby hindering their performance.

Guard against backflow in your systems with our dependable non-return Return Valve. ‘Contact Us for More Information’ to get professional advice and tailored solutions. Our team is prepared to help you with all your valve requirements.

Support and Warranty Information

Our non-return valves, like the PVC non-return valve and Wafer Type NRV Valve, are covered by complete manufacturer’s backing plus a warranty that caters to faults and breakdowns. We have all-inclusive after-sale services which involve installation assistance together with maintenance tips from knowledgeable non-return Return Valve Suppliers.

- They are used for industrial purposes such as

- Chemical industries

- Power plant industries

- Dump lines

- Wastewater management plants

- They are used for pumping systems

- Water pumping

- Metering pumps

- Feed pumps

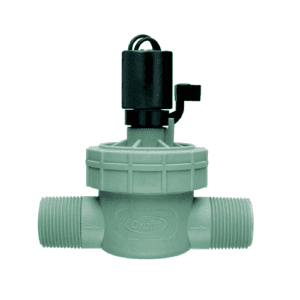

- They are used for domestic purposes

- Irrigation sprinklers

- Solar installation

- Hydraulic pump jacks

- Pumping stations

- Metering pumps

- Chromatography pumps

- Pumping stations

- Firefighter water pumps

- Hydraulic pumps

- Used in pumping systems

- Chemical industries

- Pipelines

- Vacuum systems

- Food industry

- Solar industries

- Ventilating systems

- Heating systems

- Air conditioning system

- Combi boiler system

- Fire sprinkler

- Lawn irrigation facilities

- Sewage treatment

- Wastewater management plant

- Household items

| Name | Advantages | disadvantages |

| Ball non-return valve | Can be used with all types of fluids such as liquid or in the gaseous state. Can be installed for vertical flow too. | Not suitable for high pressures. |

| Spring-loaded in line | Wide range of uses Safeguards pipes from the hammering effect. | They could not be opened up for repairing |

| Spring-loaded y type | Safeguards pipes from the hammering effect They could be opened up for maintenance and repair | They are heavier and acquire a huge space |

| Diaphragm non-return valves | They have a very flexible disc. Good sealing effect | Not economical for maintenance. |

| Butterfly non-return valves | Has faster functioning Wide range of uses | They are not suitable for very high pressure. |

| Dual non-return valves | Helps in the distribution of pressure Acts as backup if one check valve stops functioning | They are very costly and acquire huge space. |

| Swing non-return valve | They have replaceable seat rings Low turbulence and pressure drop Easy openings at a lower pressure. | The continual flapping would harm the seating elements |

- They prevent the backflow of fluid

- Self-actuated as well as automated actuated

- They are available in wide ranges as per the requirements of the customer

- Fewer moving parts

- They play a major role in preventing backflow

- They require minimal power to operate

- Fast functioning

- They perform in high as well as low pressure

- Internal parts could not be checked for repairing or maintenance

- Noise caused by slamming of discs