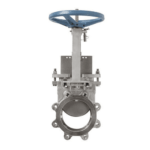

Heavy-Duty Knife Edge Gate Valve for Industrial Flow Control

The Knife Edge Gate Valve is made for severe industrial settings where accurate flow control and slurry, viscous fluids or dry bulk material shut-off are needed. This valve finds its application in the pulp and paper, wastewater treatment as well as mining industries. It can cut through thick media hence it becomes an important part of any system dealing with materials normally blocking other types of valves.

Material Specifications:

Knife Valve PVC is made of high-quality stainless steel body and tough rubber seal which provide robustness, long life span, resistance to corrosion or abrasion among others. The choice of these materials was done bearing in mind their environmental friendliness while at the same time conforming fully with applicable industry environmental standards.

Technical Specifications:

Our Knife Edge Gate Valves have a full-bore design that reduces pressure drop across the valve. They come in sizes ranging from 2” to 24” with flange connections meeting ANSI standards. Manual, electric or pneumatic actuators like Gate Valve Pneumatic can be fitted onto them thus making them suitable for use under various operational conditions. The blade’s cutting edge has been designed such that it can efficiently deal with highly concentrated abrasive substances.

Standards and Conformity

The Knife Gate Valve complies with international standards like ASTM and ISO 9001 that guarantee its quality as well as dependability. Additionally, every valve is tested according to Knife Gate Valve Manufacturer requirements for pressure and durability; it has certifications from recognized industry bodies that ensure safety measures are met during use.

Usage Instructions

Regular servicing is necessary if you want your Knife Gate Valve to perform at its peak. This involves checking the blade’s condition periodically along with that of the seals so that they may work best. It should be installed by professionals who will do it right since there are common mistakes made during installation such as misalignments which can interfere with its functioning or even expose people around it to danger. In case you need some help on troubleshooting or more detailed maintenance guidance then refer to the user manual given or seek assistance from Knife Gate Valve Manufacturers.

Applications

A knife gate valve can be used in many different areas such as mining, water treatment plants, or pulp and paper factories. This type of valve can handle thick sludge which may also contain solids that could wear away at other types of valves like slide gates. The knife edge gate variant is especially good at cutting through media with high solid content without clogging up and thereby improving system reliability. Robust construction coupled with reliability has earned these models a reputation among suppliers who deal in knife gate valves alone or those that stock them alongside other related products for sale to customers worldwide.

Features and Benefits

Features:

Strong design that can cut dense materials.

Can be actuated manually, electrically, or pneumatically, depending on need.

Cost-effective PVC options are available for less corrosive applications.

Knife edge gate valves have improved sealing properties, which prevent leakage under high-pressure conditions too.

Benefits:

Its sturdy design and ability to handle tough media ensure that this product will save on maintenance costs.

Different designs can be adapted to specific system requirements, like the Gate Valve.

Valve blockage or failure-related downtime is reduced, thus enhancing operational efficiency.

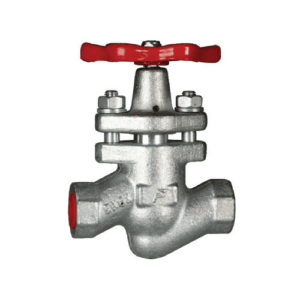

Other Products

Consider these associated items when bettering your valve systems:

Pressure Relief Valves: They are necessary for guarding against overpressure situations in systems using Knife Gate Valves.

Check Valves: It prevents backflow, which may interfere with the efficient working of the system due to reverse flow.

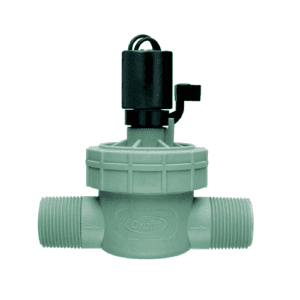

Actuators: A variety of actuators, such as pneumatic, hydraulic, and electric, can be used for automation purposes on Knife Edge Gate Valves as well as to improve their response time.

Improve your industrial systems with our Knife Edge Gate Valve of excellent quality. For instant purchasing, get in touch with us for individualized advice and solutions from our team of knowledgeable Knife Edge Gate Valve Manufacturers.

Support and Warranty Information

Our help is extensive and backed up by strong warranties on all our Knife Valves, which also include Knife Edge Valve and Valve Knife Gate models. To ensure that your equipment gives the best performance, we offer direction on how to fix it when broken down as well as operational support services, among others. We are dedicated to making sure that what we provide is reliable, hence being recognized as a trustworthy supplier team for Knife Edge Gate Valve. Besides covering defects in materials used during manufacturing processes, this warranty covers workmanship too.