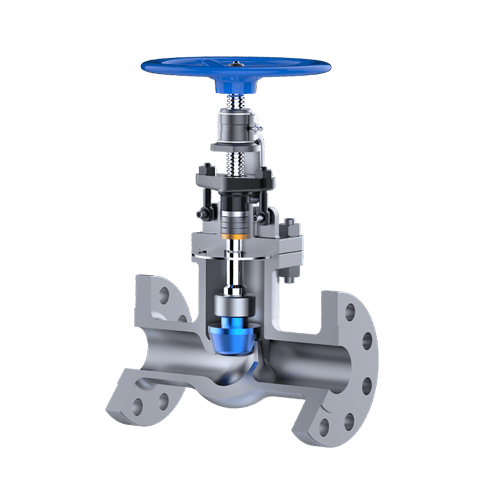

High-Precision Globe Valve for Regulated Fluid Control

They are the most vital components that control the flow within the piping systems of nearly all industries. Owing to their excellent throttling and controlling qualities of fluid, a [Globe Valve] has become a must for applications from simple water transportation to complex chemical processes. The [Globe Control Valve] has been renowned as the very accurate and reliable member in the industrial fluid control family.

Material Specifications:

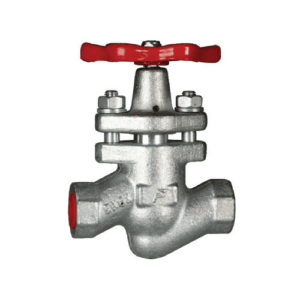

Our Globe Valves are manufactured in high-quality materials: stainless steel, cast iron, and bronze materials to guarantee durability and resistance to corrosion. Proper selection of material has to do with the specific application requirements, perhaps among them the environmental conditions of temperature and pressure, or the characteristics of the fluid. Each material has been selected based on its strength, reliability, and ability to retain integrity when exposed to the most severe conditions.

Technical Specifications:

- Sizes available from 1/4 inch to 24 inches

- Pressure ratings up to 2500 PSI

- Temperature range from -196°C to 600°C

- It comes with either flanged, screwed, or butt-weld end connections

- This way, it makes sure that the [Globe Valve] is versatile for varied applications and guarantees optimum performance over a longer period.

Standards and Compliance

Our globe valves, in particular, are manufactured adhering to internationally approved standards, among them being ASTM and ISO 9001/2000. We are the reputed [Manufacturer of Globe Valves in India] and we ensure that all the ranges of valves provided to our clients have been quality tested and prepared as per the laid down standards. Every single valve is certified to meet the global safety and quality benchmark and reassure the reliability and performance of the product to the customers. We are [Globe Valve Manufacturers], [Globe Valve Suppliers] in the market, so providing our best services to our customers.

Usage Instructions

Regular maintenance is required for optimal performance of the valve. The following are some of the maintenance tips you can consider:

- Periodically inspect for wear, particularly in the valve seat and the disc.

- This assures good stem lubrication and eliminates sticking or binding.

- Check for leaks frequently and tighten all connections as needed.

- Follow all installation instructions by [ Globe Valve Manufacturers] for proper alignment and operation.

Applications

Many industries can use a globe valve for controlled precision in flow and pressure. They have the following applications:

- Chemical Processing: Used for its ability in stringent control, which is important for handling reactive and hazardous chemicals.

- Steam Services: The [ Globe Control Valve ] is responsible for the major task of steam flow control in the system, and for monitoring pressure surges.

- Cooling Systems: Manages the temperature and flow of mediums for cooling in HVAC systems.

- Oil and Gas: Globe valves are designed robustly, hence fit for the heavy-duty services synonymous with high-pressure environments in the oil and gas service sector for extraction and processing.

Features and Benefits

Features

- Precise Flow Regulation: The main advantage of the [Globe Valve] is that it offers the potential to have accurate control over the flow; in general, processes require it.

- Durability: Their durability is because they are made of materials such as stainless steel and bronze, thus making them bear conditions to be the worst and lasting for the most life service.

- Ease of Maintenance: During the design of this product, it has taken into account that the internal parts of this product should be easily accessible, so that in case a new part needs to be inserted, the valve can again be put to its original working position without necessitating its dismount from the line.

Benefits:

- Energy Efficiency: Optimizing the flow and pressure of systems can save much energy that would otherwise be wasted with this kind of waste.

- Operational Safety: The ability to ensure that the system operates safely by providing stable control of the fluid flow in the application.

- Cost-Effective: This is a very long-lasting product that requires almost no maintenance, and so the cost of ownership is extremely low.

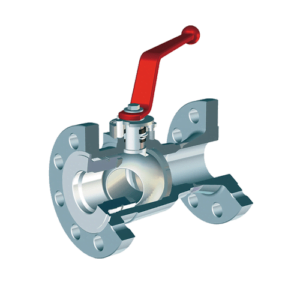

Related Products

To complement your system setup with [Globe Valve], consider integrating:

- Check Valves: Fluid flow will be ensured as one way. Thus, backflow will damage components in a system, and, of course, check valves will prevent that.

- Pressure Relief Valves: It is prepared to guard systems against high pressures through pressure relief valves.

- Actuators: They change the operating capability of the [Globe Valve] into remotely controlled and automated flow control devices.

Support and Warranty Information

Our Globe Valves, including our in-house custom-designed Globe Control Valve, carry with them a full warranty and are backed with full customer service by any reputable Globe Valve Supplier. We offer detailed installation advice, operating support, and a high-level service of troubleshooting to ensure that your valve gives trouble-free service for the life of the product.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.