Robust Multi-Purpose Gate Valve for Industrial Use

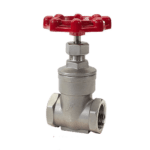

The gate valve may be a very simple mechanism, yet its function is very broadly utilized in isolating fluid flow in many piping systems; hence, it is considered important in many fields, from water management to chemical processing. The versatility is brought about by the fact that the gate valve is capable of offering a tight seal upon closure and offering very little resistance while open, and this makes it very suitable for use with both liquid and gaseous substances.

Material Specifications:

Constructed from the toughest materials on the market, such as stainless steel, cast iron, PVC, and brass, our Gate Valves are capable of withstanding a vast range of environments and chemical exposures. The [PVC Gate Valve] is resistant to corrosion and is light duty, thus being applicable to services that are less abrasive, such as water distribution, while the [Brass Gate Valve] provides for harsh conditions with additional durability.

Technical Specifications:

- Sizes available from 1/2 inch to 48 inches

- Pressure ratings up to 600 PSI

- Temperature range capabilities from -20°C to 300°C

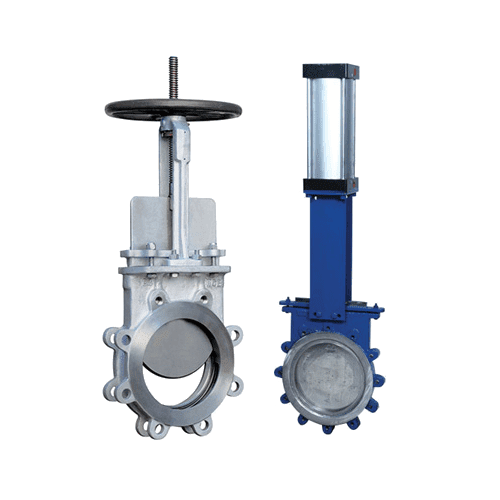

- Design choices consist of the [knife gate valve], the [slide gate valve], and the [sluice gate valve], all specially developed for certain service requirements.

- These specifications ensure that our [gate valve] can be used in a wide class of applications, industrial and residential alike.

Standards and Compliance

Further attesting to their quality and safety, our gate valves meet the most demanding of industry standards, including ASTM and ISO 9001. We are among the prominent gate valve manufacturers in India, ensuring stringent tests and quality control from procurement to final inspection of finished products. Certification of products to meet the stringent standards of safety and processes worldwide ensures a reliable solution to your requirements for fluid control.

Usage Instructions

Regular maintenance is important to help ensure maximum service life and performance from your [gate valve].

- Periodically check the valve for wear or leakage.

- Apply lubrication to the moving parts of the valve when necessary to ensure ease of movement.

- Do not overtighten the valve, as it will add undue stress to the components.

- For more detailed information on maintenance, please contact [gate valve manufacturers] or our Technical Support Department.

Applications

Applications

A gate valve is a general-purpose valve and can be used in a very wide range of service applications.

- Water Supply and Treatment: The PVC Gate Valve and the Brass Gate Valve are especially suited for municipal and industrial water supplies intended for distribution.

- Oil and Gas Industries: High-strength [Gate Valves] are applied in isolation service in oil and gas pipelines where robust performance under high pressure is required.

- Mining and Mineral Processing: The Knife Gate Valve is the right valve for slurry and other viscous media, which are, in every sense of the word, mining.

- Agricultural Irrigation: [Sluice Gate Valves] and smaller [Gate Valves] are often built into agricultural systems for the purpose of controlling huge bulk water supplies.

Features and Benefits

Features

- Leak-Proof Design: [Gate Valves] are great in providing sealing features that guarantee better leakage support and let the system work with improved efficiency.

- Diverse Material Options: Valves can be availed of in PVC, stainless steel, and brass, depending on the material selection requirement in a particular application, for enhanced performance and durability.

- Easy Maintenance: it is quite easy to access its inner parts for maintenance and repair, thus low maintenance cost.

Benefits:

- Cost-Efficiency: Competitive [Gate Valve Price] Allows us to deliver a premium product from the front of costs, ensuring that the returns are paid handsomely.

- Longevity: They are usually constructed strong and can tolerate even the harshest of conditions; therefore, they are long-lasting.

- Versatility: The different types include a knife gate valve, slide gate valve, sluice gate valve, and a product range that can serve numerous applications for fluid control.

Related Products

For a comprehensive fluid control system, consider these complementary products:

- [Check Valves]: Prevents backflow, and if the gate valve is open, the system is guarded.

- [Butterfly Valves]: In some services, a faster shut-off alternative to the gate valves.

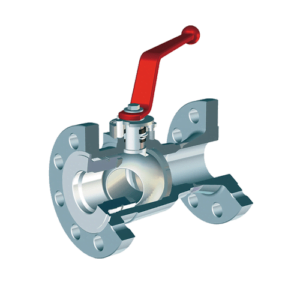

- [Ball Valves]: Another quick shut-off flow control for use with gases or in compact systems.

Support and Warranty Information

Our [gate valves]. Among these are the [knife gate valves], and all of our gate valves are supported and have warranty coverage. We offer in-depth support with installation, operation, and troubleshooting to ensure maximum efficiency over the service life.