Robust and Reliable Diaphragm Valve for Industrial Applications

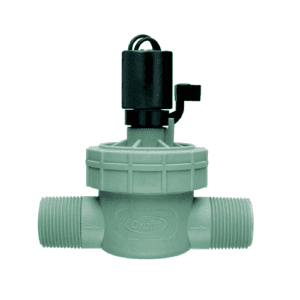

A Diaphragm Valve, which can be applied to control fluids in various ways, is created to adjust, reduce, or stop the flow completely without the usual damage associated with other valves. This valve is best suited for biopharmaceuticals, food processing, and water treatment sectors because it is very dependable and has specific control capabilities that match the individual needs of these industries. In more complex or distant systems, the Pneumatic Diaphragm Valve variation provides automated control that improves efficiency during operation.

Material Specification:

Our products are made from different materials, including PVCs (Polyvinyl Chlorides), stainless steels and some proprietary alloys, all sourced from leading manufacturers dealing with diaphragm valves globally; this ensures they meet durability and performance standards required by industries worldwide. We choose what kind of material to use when producing our items based on their ability to work with many types of liquids while resisting corrosion even at high temperatures, besides being environmentally friendly where necessary.

Technical Specifications:

Our line offers a variety of sizes and types designed for different industrial applications ranging from small to large scale. These specifications include valve size (1/2” – 12”), operating pressures, and temperature ranges that can be managed by the valves. The diaphragm control valves are made for accurate flow modulation aimed at maintaining optimum process conditions.

Standards and Compliance

The diaphragm valve meets international standards such as ASTM or ISO, which are put in place to ensure quality and safety around the world. We subject each of our units to rigorous tests for them not only to meet but surpass these requirements; this makes them dependable when used in critical areas of industrial applications where failure can lead to catastrophic occurrences. Also, some certifications accompany most of our products, showing that they have been tested fit for use within delicate environments like those found within food processing or pharmaceutical manufacturing sectors.

Usage Instructions

To make the most of your diaphragm valve in terms of efficiency and durability, you should do maintenance regularly. This should involve checking for signs of wearing out or malfunctioning, especially with pneumatic diaphragm valves used continuously. Installation must follow the instructions given in our detailed manual so as not to experience common problems like wrong fitting or misalignment, which may affect its performance. Troubleshooting procedures and common issue resolution tips are also provided for the ongoing best operation guarantee.

Applications

The diaphragm valve finds wide usage across industries that require media control precision as well as purity during handling. For instance, chemical processing plants, pharmaceutical manufacturing companies, and food production systems, among other sectors, fall within its scope of utilization. Fine throttling capabilities and minimum contamination risk demand are best met by using a diaphragm control valve, while an automated control system with remote operations can benefit greatly from employing a pneumatic diaphragm valve.

Features and Benefits

Features

- Leak-proof design that reduces the risk of contamination and ensures fluid integrity.

- Available in manual or automated versions for different operational requirements.

- Produced from premium materials that resist corrosion and provide excellent durability.

- Configurable design to accommodate various connection standards and operational specifications.

Benefits:

- Improves process reliability and safety through accurate flow control with minimum leakage.

- Low maintenance needs due to strong construction using quality materials from manufacturers of diaphragm valves.

- Enhances operational efficiency by reducing downtimes while allowing easy integration into existing systems where necessary.

- A cost-effective solution with a competitive price list for diaphragm valves in India offers a good return on investment.

Related Products

For systems needing extra components, check out these related products:

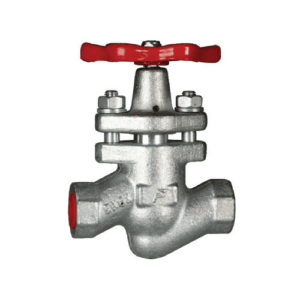

Gate Valves: For pipeline on/off controls

Globe Valves: Ideal for high-pressure regulation flow applications

Check Valves: Prevents backflow and protects fluid system critical components.

A complete solution for controlling flow can be obtained by using any of these products alongside the Diaphragm Valve. For more detailed information about compatibility and specifications, please visit our website.

Ensure safety and maximize efficiency in your system today through the selection of our dependable Diaphragm Valve. “Contact Us” if you need more information or want to discuss an application in depth. We are here to help with expert advice throughout the process so that you end up with exactly what is required for your situation.

Support and Warranty Information

We cover all models under our warranty, including pneumatic Pneumatic Diaphragm Valve as well as control valves like Diaphragm Control Valve, because we believe in quality assurance backed by commitment. Technical support staffed by professionals who have worked for years as manufacturer representatives is available should you require it; warranty details can also be found along with other resources designed around installation, operation, and maintenance which ensure that your valve will work reliably over time.