Durable High-Precision Ball Valve for Industrial Use

The ball valve is a very important part that is used in many industrial plumbing systems. It can be utilized to control the flow of liquids and gases in residential areas as well. Its reliability and simplicity make it perfect for applications where accurate regulation of flow rate is necessary. This valve is also popular because of its strength and low maintenance cost, hence being affordable at all places.

Material Specifications:

We manufacture our valves using only the best materials, such as stainless steel ball valves or PVC ball valves, which can be applied under different fluid types or environmental conditions since they are made with this consideration in mind too. Such materials were chosen based on their ability to resist corrosion and last long, thus ensuring every single valve works at its best even when exposed to extreme conditions.

Technical Specifications:

These series of ball valves are available from half an inch up to twelve inches in size range and capable of withstanding pressures of one thousand pounds per square inch (1000 psi) while operating within a temperature bracket starting from negative twenty-nine degrees Celsius (-29°C) going upto two hundred fifty degrees Celsius (250°C). These ball valves have three-way configurations, like the 3-way ball valve, enabling you to connect them flexibly and allowing fluid to move in any direction desired by the user. They were built not only for efficiency but also for leakproofness, considering that each comes with user-friendly handles that clearly show open-close positions alongside indicators indicating where exactly leakage might occur during the operation process.

Standards and adherence

All our valves, inclusive of the SS Ball Valve in demand, are made to meet global standards such as ISO 9001, ASTM, and ANSI. What these certificates do is highlight our dedication towards quality and safety, thereby ensuring that clients get long-lasting products capable of performing well even under extreme conditions. Also, they comply with environmental laws, thus showing how much effort we are putting into reducing ecological impacts.

Instructions for use

For optimum performance of your Ball Valve, you should perform routine maintenance like cleaning its interior parts from time to time as well as checking whether there are any leaks or not. When fixing this device, ensure only qualified technicians do it because if mishandled, some common problems may arise, such as cross-threaded or over-tightening, which might affect its functionality. In case of any challenges, refer to a comprehensive manual provided with every purchase for more information on how to troubleshoot and other related concerns.

Applications

The ball valve is flexible and can be used in many different situations, which makes it the perfect choice for a wide range of applications. These can range from residential water systems to high-stake industrial processes. For medium-sized applications such as domestic water distribution, the 1-inch ball valve would do well, while smaller lines often found in home plumbing systems might use a 1-inch one. Ball float valves are great for controlling levels in tanks, whereas flanged ball valves work best when dealing with larger pipelines that need strong connections.

Features and Benefits

Features:

- Strong design with either flanged ends or threaded connections available

- Can be made out of a variety of materials like PVCs, stainless steel, or brass, so they will fit any system’s needs.

- Configurations offered include inch ball valves; half-inch ball valves and three-ball valves, giving full control over flow direction and volume

- Comes with easy-to-use lever handles as well as visual indicators for open/close status

Benefits:

- The Ball Valve provides a tight seal with low torque, so it is not difficult to operate, which reduces work fatigue and increases efficiency.

- Long life span and less need for maintenance due to the use of high-quality materials such as Stainless Steel Ball Valves or PVC Ball Valves.

- In applications involving water, gas, or oil, there is an improved safety record alongside greater reliability that prevents leaks and ensures system stability.

- Ball Float Valve maintains required levels of water automatically, hence enhancing automation within systems while reducing monitoring needs

What you might need

- Below are some other items related to valves that can be used together with them to improve their performance within your system:

- Butterfly Valves: These are used when there is a need for easy flow control along large pipes where pressure drops should be kept at minimum levels.

- Check Valves: They help to prevent backward flow in any given pipeline, thereby ensuring continuous one-way direction of flow for media through all times.

- Gate Valves: They should be considered ideal if straight-line flows are only allowed through with little restrictions even when fully opened during application processes.

These products can be viewed in detail or ordered from our website; they also work best when coupled with any Ball Valve products for compatibility reasons.

Support and Warranty Information

Any kind of help you need regarding the Ball valve is promised by Induskart. We provide a full one-year warranty which covers material and workmanship defects as well as setup, maintenance, and troubleshooting support from our team of experts dedicated to ensuring your satisfaction with their service to keep up with being ranked among top-rated Ball Valve Manufacturers in India and Ball Valve Suppliers.

Types of Ball Valve

According to Flow of circuit

- 2 Way Ball Valve (L type)

- 3 Way Ball Valve (T type)

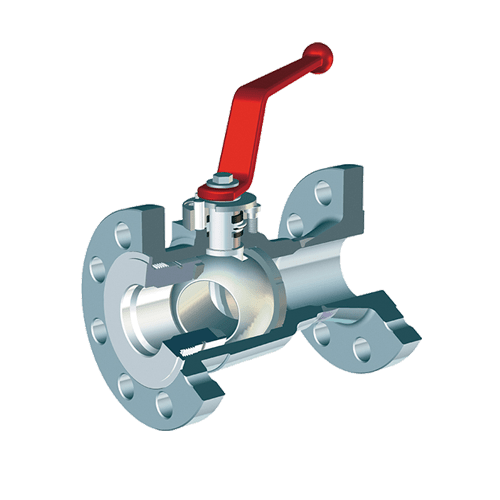

According to Design

- Single Piece Design Ball Valve

- Two Piece Design Ball Valve

- Three Piece Design Ball Valve

According to MOC

- PVC Ball Valve

- Cast Steel Ball Valve

- Cast Iron Ball Valve

- Brass Ball Valve

- SS Ball Valves

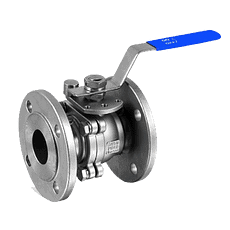

According to End Connection

- Flanged End Ball Valve

- Screwed End Ball Valve

- TC End Ball Valve

According to the Operation

- Electric Ball Valve

- Manual Ball Valve

- Pneumatic Ball Valve

Some of the Reputed brands in market manufacture Ball valves are Zoloto, Leader, Sant, Indusroof, L&T, Audco and many more.

We at Indusroof can supply all the above mentioned ball valves, and other valves as well for your project requirement.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.