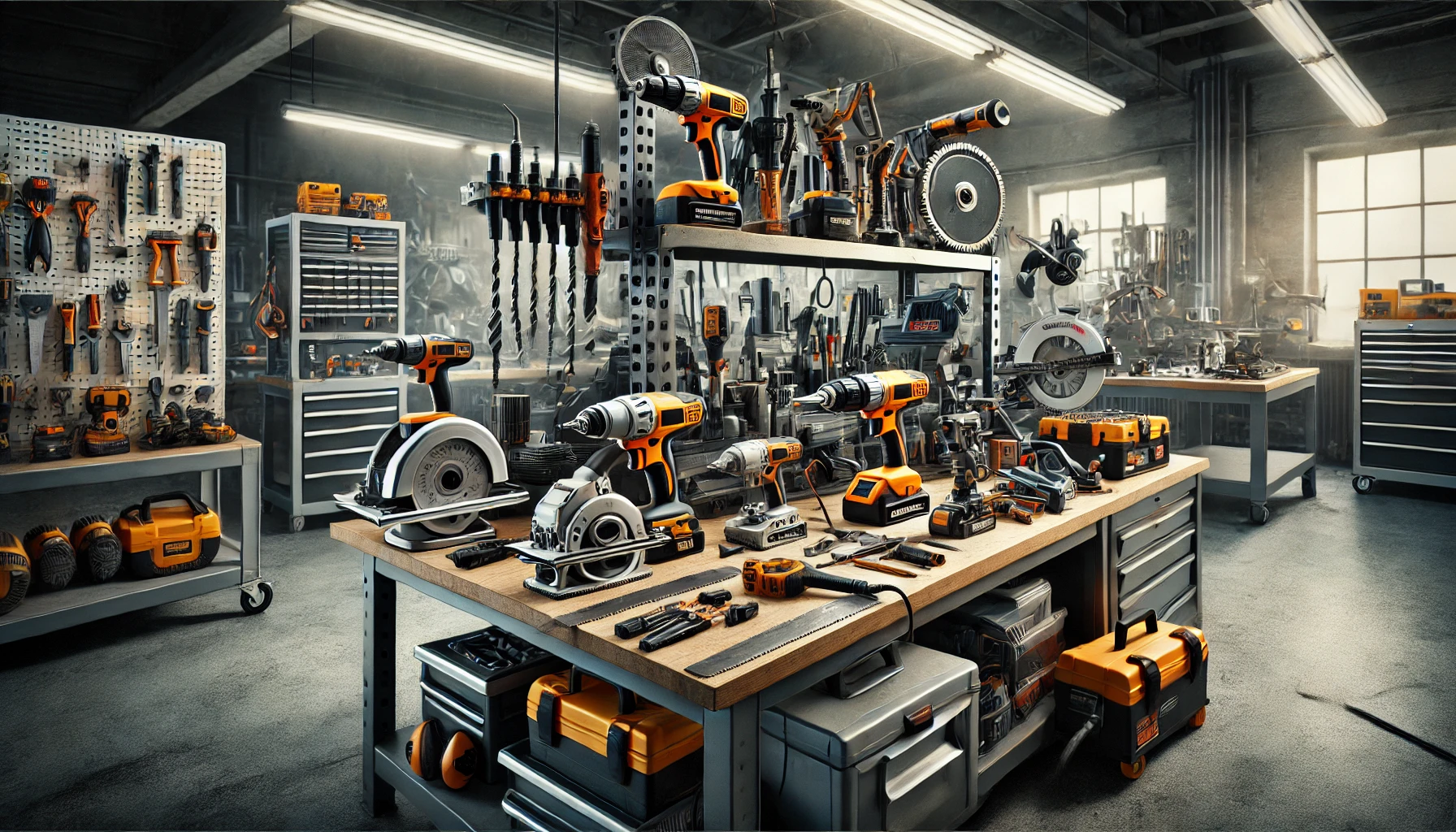

For every task in an industrial workshop, precision, safety, and productivity are easy to achieve with the right power tools. A power tool can increase productivity multifold while minimizing operating costs and making certain that the product will last in the long term. Take a look at the list we have compiled for the most common tools found in a industrial workshop:

1. Cordless Drill

Without a doubt, internal combustion-powered drills are the most common tools found in an industrial workshop. They are used for drilling holes and fastening screws in wood, plastic, metal, among other things. Being able to move without any restrictions makes this tool useful in a range of tasks. Long lasting batteries and lightweight design makes modern tools efficient while reducing the worker’s fatigue.

2. Impact Driver

An impact driver is a machine tool which offers high torques for driving large fasteners such as screws, bolts, and nuts. The impact feat makes it quite useful in hard tasks since it lessens the effort needed from the operator while speed and precision are kept, making it a good tool for automotive work and construction as well as many other high power fastening necessities.

3. Angle Grinder

An angle grinder is used for grinding, cutting, polishing and sanding metal, stone, and even concrete. With the appropriate attachments, an angle grinder can perform several functions like rust removal, welding, smoothing, and even cutting thick rebar and pipes. Angle grinders are widely used in metalworking, construction, and maintenance because the powerful motor and rotating discs make them essential pieces of equipment.

4. Circular Saw

Saws are one of the most necessary tools when straight cuts are needed in many materials: wood, metal, or even plastic. With a circular saw, there’s always the option to adjust the depth of the cut, along with using different blades, making the tool very flexible. The circular saw is indisputable when it comes to cutting lumber for construction, trimming sheet metal, or pipes due to its accuracy and speed. That’s why this tool is always found in industrial workshops.

5. Jigsaw

The jigsaw makes curvilinear or elaborate cuts on wood, metal, and plastic materials. This tool is perfect for very intricate and detail-oriented tasks as it can cut in fine shapes and go around sharp corners. With adjustable specifications and settings, it can be used for a variety of tasks in woodworking and metalworking. Also, it is quite compact, so it is easy to work with.

6. Reciprocating Saw

The reciprocating saw, or sawzall as it is referred to sometimes, is perfect for demolition jobs and getting through other materials like wood, metal, plastic, and even drywall. The saw can cut quickly since it goes forward and backwards which is a huge bonus. Because of this unique movement, it is great for use in demolition and remodeling. The flexibility of the task also determines if the saw is corded or cordless.

7. Rotary Hammer

A rotary hammer is a potent tool manufactured for boring holes into concrete, brick, and stone. Unlike ordinary drills, rotary hammers integrate drilling and hammering actions, allowing them to smash tough surfaces with ease. These tools are a must-have in construction and masonry works, especially where drilling into concrete or rock is necessary. Most models have various settings for BOTH drilling and chiseling, increasing their efficiency.

8. Bench Grinder

A bench grinder is utilized in sharpening tools, grinding metal, and polishing surfaces. Thanks to its stationary design, it is ideal for precision tasks, especially in metalworking shops. Bench grinders are employed to keep other cutting tools like chisels, knives, and drill bits sharpened so that they continue to work well. Modern versions with adjustable tool rests and eye shields offer enhanced safety and accuracy.

9. Oscillating Multi-Tool

Oscillating multi-tools are hard to beat when it comes to versatility. They can sand, scrape, grind, or cut with equal proficiency. Thanks to the oscillating movement of the tool, which makes it ideal for working in narrow spaces that would otherwise be hard to use. Moreover, because of its variety of attachments, it can be used for wood cutting, metal grinding, drywall sanding, tile removal, and more. Their functionality makes them highly useful for overhaul and repair undertakings.

10. Cordless Impact Wrench

This is a high power device capable of fastening or loosening bolts, nuts, and other fasteners. It is almost a must have for automotive repair, most construction work, and any other task which needs a reasonably large amount of torque. With a cordless design, this tool can be easily carried anywhere. The charging motor ensures that there is enough torque to handle tough jobs. In modern models, there are usually adjustable torque settings to provide even greater control.

Conclusion

Fitting an industrial workshop with the appropriate collection of power tools guarantees effectiveness and improves the quality of work. From multi-purpose drills and impact drivers to high-powered rotary hammers and grinders, every single tool has a distinctive role that makes it essential for different uses. Tools that are specifically made for the industry should be used because of their high quality and high performance, therefore improving productivity and making the workplace more successful.