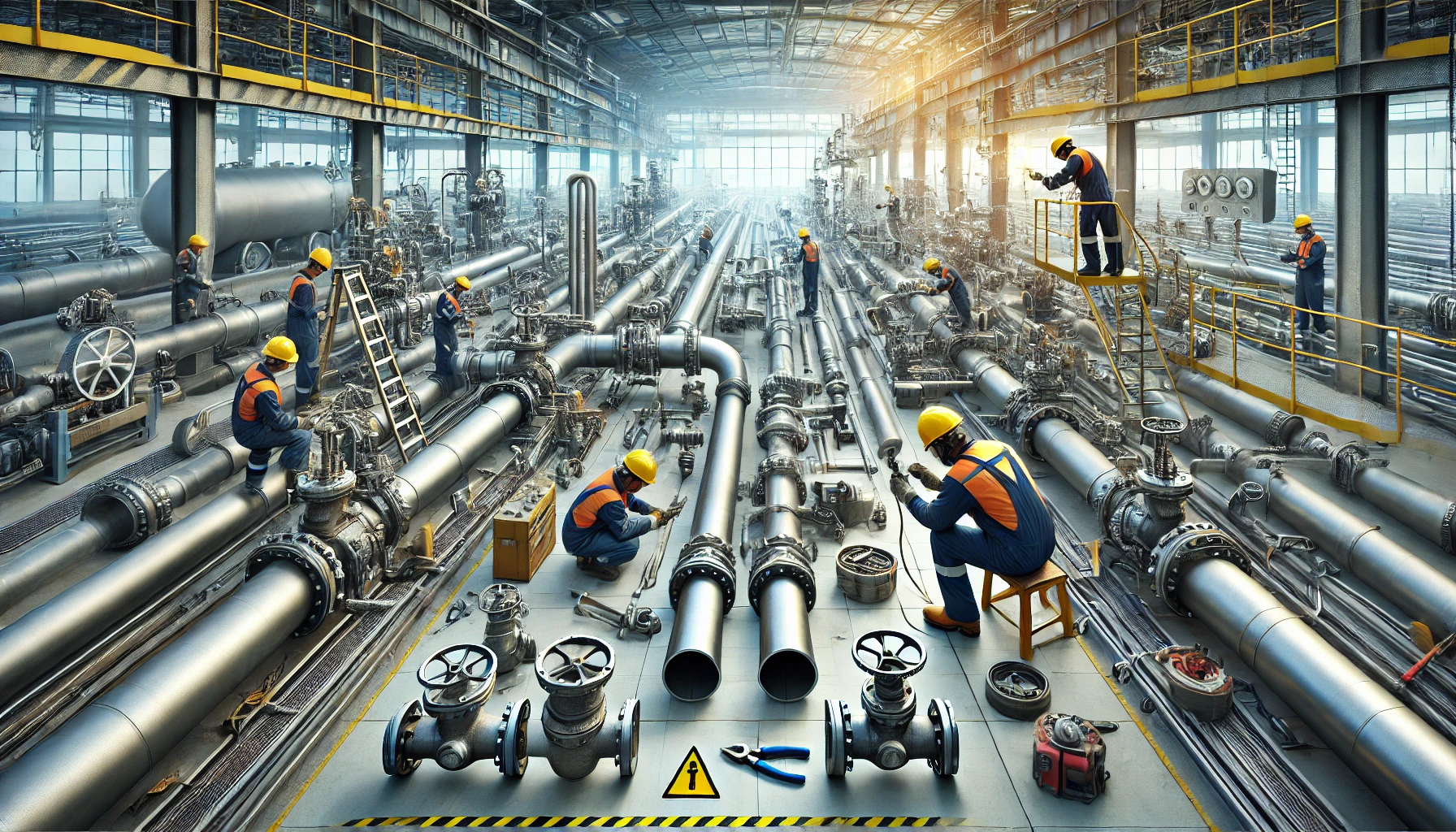

The high-pressure piping systems are diligently working in the background and make sure that multiple processes are seamlessly executed during industrial work. These systems help in operating machines and fluids that are very important for the industries which are used for hyperbaric transport. The ease of access through which these systems can be utilized is great because the way they are installed determines how efficient, safe, and durable they are.

This is where Induskart comes in for aid as they Induskart is an industry goods supplier having more than a decade worth of experience, so that you do not have to run around looking for sourced multipurpose valves, safety products or even industrial valves and pipe fittings. Unlike many other suppliers, they understand the fabrication and implementation challenges which makes them knowledgeable on how to help their customers with effective servicing and proper installation.

Understanding High-Pressure Piping Systems

Definition and Importance: High-pressure piping systems are used to contain and transport fluids in high-pressure and demanding industrial environments. These systems are especially important in high pace industries in the transport of gases and liquids as most of the processes. These systems in its working condition also ensure and enable operational efficiency and safety as well. The high-pressure piping system should be intact, as any kind of failure may lead to operational failure and may create safety risks.

Materials Used: Selection of the material for high pressure piping is critical and will depend on its application under judgement. combustible fluids are best transported through carbon steel, stainless steel or even now and then using alloys depending upon the use. Induskart, have been providing best industrial solutions and have built a trust on offering various materials as part of their carbon steel, stainless steel and alloy range.

Common Applications: The high-pressure piping systems are used in an array of industries as a hallmark of their flexibility and utility. The most notable examples are petrochemicals, pharmaceuticals, water treatment, and manufacturing. Induskart has broad experience in these industries and, because of its extensive product range, does not only provide components of the systems but also offers full system installation and maintenance services, posing as an industry expert. Their participation in various fields like HVAC, oil and gas refineries, and electric power showcases the depth of their reach and the confidence put in their products and services.

Pre Installation Planning

Assessing the Installation Site: Evaluation of the site should include steps such as obtaining the floor plan and having a walkthrough of the site before mobilization to construction along with a deep inspection. Understanding the site enables preparation of the area where heavy equipment will be operated. Preparation of the site includes confirming that the installation is clean and free from obstructions. Evaluation of the site done prior facilitates the design of the piping routes and placement of the supports which is critical for a high-pressure system.

Choosing the Right Materials and Tools: The installment of any construction project requires the use of appropriate tools and materials, and this one is no exception. Induskart offers a wide selection of premium industrial products that includes pipes and fittings, welding supplies, safety equipment, and even tools suitable for high-pressure piping systems, thus ensuring that everything one needs is at hand to complete an entire project from its design to execution. With Induskart, you are sure to get quality materials that are tailored to the needs of the specific project.

Safety Considerations and Compliance with Industry Standards: Industry regulations must be followed without exception during the installation of high pressure piping systems. Using safety equipment, adhering to protocols to meet predetermined standards, and paving the way for other necessary steps required to guarantee that all components blend into a streamlined unit is essential for the operability of the system. Induskart’s unwavering devotion to safety and quality guarantees that the products offered meet those standards.

Step by Step Installation Process

Step 1: Site Preparation: Begin with site preparation for the installation, and this entails removing all forms of encumbrance in the surrounding area, marking the appropriate area with safety signs, and confirming that all the tools and equipment needed for the installation are proficiently supplied and within reach.

Step 2: Inspecting and Managing Materials: Handle and inspect the materials upon receiving them to ensure there are no visible damages. Also, use caution so as not to damage the materials. Induskart’s quality workmanship comes into effect here because their products have undergone sufficient quality checks.

Step 3: Pipe Cutting And Threading: All pieces of pipe must be cut to the necessary dimensions, so precise measuring is critical. After cutting, the pipes need to be threaded or prepared for welding, depending on the type of connection required.

Step 4: Fitting and Assembly: Fit the pipes with appropriate fittings in accordance to the already predetermined schematic. Confirm that all joints and alignments are fully secured. This is the accuracy needed to make certain that there are no leaks and that the system remains operational.

Step 5: Techniques of Joining and Welding: Proper techniques for welding should be used for welded joints. There must be certified welders to perform these particular steps so that the welds will pass the strength and safety criteria.

Step 6: Inspection and Testing Under Pressure: A pressure test is carried out after the assembling of the system in order to check if there are any leaks and check if the system is capable of withstanding operational pressures. Unsurpassed scrutiny during this phase of the construction is key to achieving the needed longevity and safety.

Maintenance and Troubleshooting

Routine Maintenance Tips for Longevity and Efficiency: For high-pressure piping systems to function efficiently, regular maintenance is imperative. Every system requires periodic inspections for leaks and checking wear, along with all fittings and valves operational. Cleaning schedules and corrosion prevention also increase the effectiveness of the system.

Troubleshooting Common Issues: leakes, fluctuations in pressure and blocks are all common issues that require immediate attention to prevent safety hazards and system downtimes. Quick-response strategies are highly effective and prevent prolonged system downtime.

How Induskart’s Product Range Assists in Maintenance and Troubleshooting:

Induskart provides to its customers an all encompassing maintenance toolkit which aids in the troubleshooting of high-pressure piping systems. The reliability of Induskart’s products guarantees system performance and diminishes the severity and frequency of issues.

Enhancing Safety and Efficiency

- Importance of Using Quality Components: Using high quality components from dependable brands like Induskart significantly decrease the chances of high-pressure system failures and repeatedly bolster operational reliability making them a necessity.

- Advanced Tools and Accessories for High-Pressure Piping: The modern accessories and tools of Induskart increase both the performance and the safety of high-pressure piping systems. Induskart has modern tools and accessories critical for a piping system, and they can be found in the Induskart product catalog.

Conclusion

This guide explained how to install, maintain, and troubleshoot high-pressure industrial piping systems and their components. Every step matters. Quality execution starts with precise planning, consideration of all components, careful installation, and then comprehensive maintenance throughout.

For this purpose, Induskart can be called a guide. Their industry knowledge and diverse products are well suited for such complicated systems. Induskart ensures safe and optimal installations by providing high-quality materials and tools paired with reliable guidance and support.

With all the accuracy, efficiency, and safety required in industrial piping, finding the right partner who offers all three can be challenging. Induskart meets that challenge by providing not only products but solutions that further enable the industrial community to easily execute successful operations.