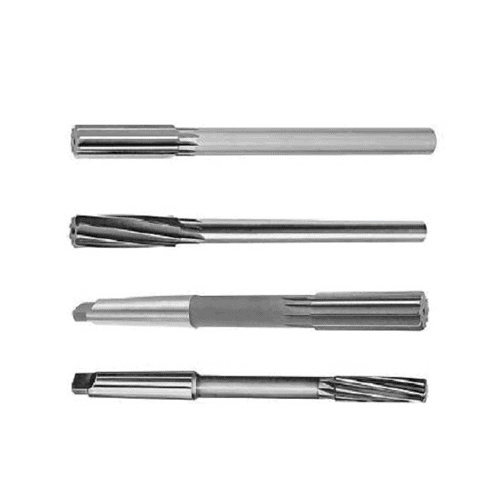

Highly Accurate Hole Enlarging Tools

Reamers are essential to metalworking, providing a way of increasing the size of existing holes with high precision, smooth finishes and maintenance of tight tolerances. These tools are very useful for exact dimensions and better surface finish mostly employed in operations across the machining industries.

Material Specifications

Our reamers are made from cobalt alloys, carbide and high-speed steel (HSS) to provide robustness, wear-resistance as well as accuracy. These materials were chosen because they have long-lasting durability and can retain sharp cutting edges under heavy use ensuring dependable performance for years.

Technical Specifications

We offer different models of reamers that suit all your reaming needs:

Hand Reamer: For manual hole enlargement processes that come in either fixed or adjustable types.

Machine Reamer: It is used on machines like drilling presses as well as milling machines where extreme precision is required during reaming process.

Endodontic Reamer: Primarily used in dental treatments especially root canal procedures.

Tapered Reamer: This tool creates new or enlarges already tapered holes.

Adjustable Reamer: Its blades can be adjusted based on the diameter of various holes it can fit into .

Drill Reamer: This tool combines both drilling and reaming functions hence saving time.

Popular Models and Sizes:

Peeso Reamer – It is sometimes referred to as a Peeso drill which is sued for shaping the canal after an endodontic post has been placed.

Tapered Reamer – Available from 1/8” up to 1”.

Adjustable Reamer — covers hole diameters ranging from 1/4 to 2 inches

Standards and Compliance

Each type of our reamers complies with international standards such as ISO and ANSI. We always test our products strictly that fulfills these requirements so that we can assure their dependability during machining processes within their specified applications.

Usage Instructions

To get the best performance and safety during the usage of reamer, follow these rules:

Choose the correct type and size of a reamer for the job.

Pre-drill a hole smaller than the final diameter of the reamer to be used.

Use adequate lubrication for reduced friction and extended tool life.

Operate the reaming tool at recommended speeds and feeds depending on the material being machined.

Inspect it regularly, keeping it sharp and precise. For detailed operational instructions and maintenance tips, please refer to your user manual or contact our technical support team.

Applications

Reamers are valuable tools in various industries that require accurate finishing of holes, as shown below:

Automotive: For making accurate holes on engine components as well as mechanical assemblies.

Aerospace: Used in the production of airplane parts with fine tolerances.

Manufacturing: Essential for finishing metallic part’s holes, including those for making other tools like drills.

Dental: Root canal procedures require endodontic reamers.

Machining: Suitable for creating accurate holes in metal projects requiring machining processes such as drilling operation

Features and Benefits

Features:

High-Quality Materials: HSS, carbide, cobalt alloy for durability and precision, respectively.

Variety of Types — Hand reamers, machine reamers, endodontic reamers, etc..

Precision Ground Edges: Facilitates proper enlargement of a hole with soothness and accuracy.

Adjustable Options: This leads to different hole sizes depending on adjustable reamers.’

Benefits:

Accuracy: Accurate hole dimensions along with superior finishes

Versatility: Applicable across numerous industries

Durability: Still performs under extreme conditions

Efficiency: Combined drilling and reaming operations reduces time spent machining

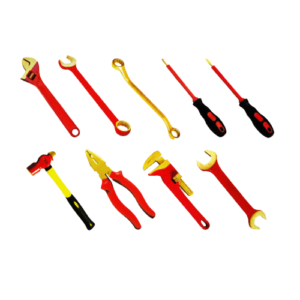

Related Products

Complete your machinist toolbox with these supplementary products:

Drill Bits: Good-quality bits that can be applied before using a reamer to create pilot holes. _ _

Lubricants encourage a smooth operation while lengthening the lifespan of your tools.

Machining Tools: In addition to your reamers, there are other precision instruments that you may need.

Call to Action

Improve your machining operations using our good-quality [Reamers]. Press “Add to Cart” for immediate purchase, “Request a Quote” for bulk pricing, or “Contact Us for More Information” for customized solutions. Our experienced team from [reamer manufacturers in India] is ready to help you choose the right [reamers] that are suitable for you.

Support and Warranty Information

Our [reamers], namely [hand reamers], [machine reamers], and [tapered reamers], come with a comprehensive warranty and full customer support from dependable Indian manufacturers. We provide usage guidance, operational assistance, and troubleshooting services so as to ensure optimum performance throughout their lifetime.