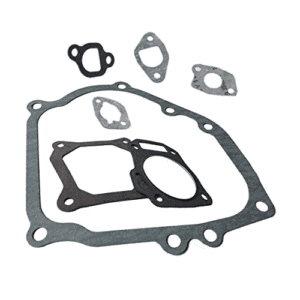

Ring Gaskets

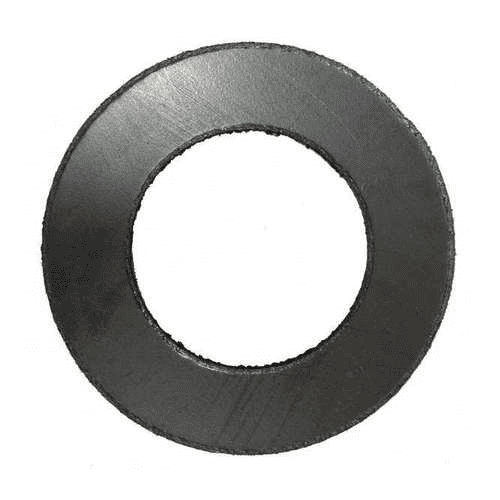

[Ring Gaskets] are components used in several areas of industry to provide a proper seal between two flat surfaces. They are known for their superior sealing ability and capability to resist increased temperature and pressure environments. They find wide applications in various industries like oil and gas, chemical processing, and petrochemicals.

Material Specifications

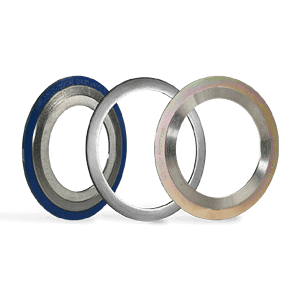

Our [Ring Gaskets] are crafted from high-quality materials such as PTFE, nitrile, or rubber, which confer excellent resistance to chemicals, flexibility, and durability. [RTJ Gasket], [Nitrile O Ring], or [Rubber Gasket Ring] varieties tend to offer better performance in sealing applications, giving secure links with long term stability.

Technical Specifications

[Ring Gaskets] come in various sizes, typically ranging from 1/2 inch up to 24 inches across. Some of the designs available include [O Ring Gasket], [Ring Joint Gasket] or even [Seal O Ring]. In addition, gasket diameter, thickness, and material composition, together with temperature and pressure ratings, can be specified precisely.

Standards and Compliance

Every single [Ring Gasket] is ASTM /ASME/ISO9001 compliant, meaning it follows international standards laid down by these organizations. As prominent manufacturers of ring gaskets, we take our products through rigorous tests before they can be released into the market, thus endowing our customers with confidence regarding safety as well as dependability. Certification from suppliers ensures adherence to service excellence along with other quality management principles they may have set aside for themselves.

Usage Instructions

For optimum efficiency as well as longevity, ensure you follow the installation instructions provided for your [Ring Gasket]. Make sure you clean the mating surfaces and remove any debris or dirt before placing the gasket. Tighten the bolts evenly so that they seal consistently. For a detailed description, refer to the user manual or call our technical support team.

Applications

The [Ring Gasket] is a vital part of numerous sealing applications that require efficient and leak-free connections. It can be observed to play significant roles in systems such as oil and gas pipelines, chemical processing plants, and the petrochemical industry, among others. The [Ring Joint Gasket] version has been specifically tailored for use in high pressure environments where an impermeable seal must be created.

The [Ring Gasket], on the other hand, is resistant to chemicals and abrasion that occurs in both high temperature and pressure conditions. Moreover, it features strong design for it to perform well in different circumstances. Similarly, the [Nitrile O Ring] is chosen due to its flexibility in making secure connections which are easy to separate.

The [Ring Gasket], therefore, ensures a tight connection with smooth flow in stressful environment’s applications. Its hardy nature guarantees longevity while staying reliable when used under tough situations. For instance, ring gaskets have a wide range of types made by manufacturers like; [Ring Gasket Manufacturers] at individual firm levels catering for specific needs within industries looking forward to exacting specifications on engineered or assured quality supplies.

Features and Benefits

Features:

Superior chemical resistance and flexibility derive from materials of highest quality available.

This attribute makes it most suited for use as a critical sealant, as it supports heavy loads, creating such ability.

On top of this being versatile, [Ring Gasket] also allows quick securing down, thus minimizing downtimes alongside labour charges.

Benefits:

The construction materials and the design ensure a longer lifespan with minimum required maintenance services at any given time.

Ring Gasket is able to have smooth flow transitions that make it more reliable and safer.

For firms that wish to achieve high quality sealing products at pocket-friendly prices, there are competitive Ring Gasket suppliers in the market.

Related Products

If you want a fully protected and effective system, these other related products can be added.

Piping Accessories: Offers leak tight joints for various piping purposes.

Control Valves: It offers regulated flow with respect to the ring gasket sealant qualities.

Jointing Material (Sealing Sheets): Ensures no leaks in pipe connections within the plant, extends its life span and maintains the desired flow rate efficiency.

Call To Action

Ask for our wholesale price list by clicking on “Request a Quote” or order through “Contact Us for More Information.” Our team of experts from [ring gasket manufacturers] will help you choose which gaskets best suit your needs specifically.

Support/Warrantee Details

The Ring Gasket comes with a warranty that covers all kinds of issues, backed by reputable Ring Gasket suppliers. We also offer guidance services during installation, operational support, as well as troubleshooting assistance needed to enable the optimum functioning of your gaskets’ through their lifecycle.