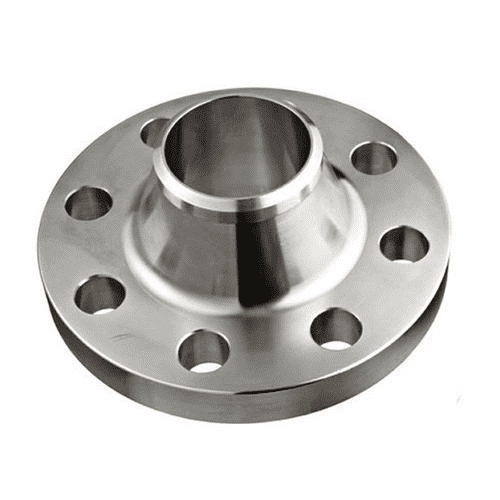

Weld Neck Flange

The long [width neck flange] is a critical product in different piping systems when users turn to join pipes, valves, pumps, and any other equipment. It is specially designed to offer a safe and tight joint. Therefore, it finds broad application in the oil and gas chemical processing as well as power generation.

Material Specifications

Enough group-long [wedge neck flanges] are fabricated from stainless steel, carbon steel, and aluminum of unbeatable strength as well as corrosion-resistant endurance in a long-life span. Our aluminum long weld neck flanges are specially accredited for lightweight and corrosion resistivity and are adequately suited for some industries.

Technical Specifications

The long neck [Weld Neck Flanges] come in a comprehensive range of sizes from 1/2 inch to 48 inch, which leaves at your disposal enough room to pick the right size that befits your piping needs. They work at allowed pressures of 2500 psi and temperatures of -29°C to 600°C. Available types include [Long Weld Neck Flange], [wnrf flange] also known as the (Weld Neck Raised Face) fitting. All the types are specially designed to perform in various operation conditions.

Standards and Compliance

All long neck [width neck flanges] are specially fabricated to comply with ASTM, ASME, and the required ISO 9001. As one of the prominent long neck flange manufacturers in India, we specially run our products to ascertain their compliance with requirements before giving them to customers. Certification from the top-end long neck weld neck flange suppliers is a guarantee of unquestionable quality management and customer service excellence.

Usage Instructions

For you to get the best from a long neck weld neck flange, it is recommended that you regularly service the equipment. The installation must be carried out according to the orientation provided by [Weld Neck Flange Manufacturers in India] to avoid top issues such as misalignment that may compromise performance. For more detailed maintenance information and troubleshooting, refer to the user manual or contact our technical support team.

Applications

The [Weld Neck Flange] is well suited for numerous systems to provide a fully secure and leak-proof connection. It can be effectively used in vast applications like oil and gas pipelines, chemical processing plants, and power generation stations. The [Long Weld Neck Flange] is used in critical applications where high-pressure and high-temperature conditions are prevalent.

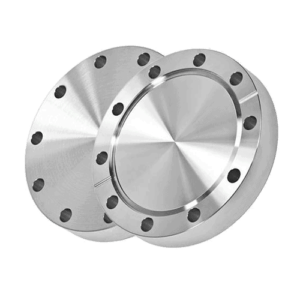

The [Weld Neck Flange] will be ideally used for water and wastewater management systems for assured leak-proof connections and not allowing the leakage of any pipelines. The strength of the [widened neck flange] will ensure its durability in various environments. The [Weld Neck Raised Face (wnrf flange)] shall be used in considerably placed applications or applications where a tight seal is of utmost importance.

The [Weld Neck Flange] is pressure-rated, wherein welding up ensures that the connection is strong and not prone to any kind of leakage. Its highly sturdy mechanism would ensure durability, and its robust method would ensure reliability. [Weld Neck Flange Manufacturers in India] produce a wide range of weld neck flanges, including customized solutions to meet specific industrial requirements. This adaptability makes them preferred suppliers for projects requiring precise engineering and reliability.

Features and Benefits

Features:

- The advanced sealing technology used will ensure tight closure in the [widened neck flange], preventing any leakage at all.

- It imparts a long welding neck flange, which is ruggedly built for use in higher pressure and temperature applications.

- The wide range in the [Aluminum Weld Neck Flanges] makes it rather easy to install and maintain, which in turn reduces downtime and labor costs.

Benefits:

- Extended service life and low maintenance costs due to heavy-duty materials of construction and design.

- The Weld Neck Flange is very effective in their leak tightness, therefore increasing the reliability of the system and protecting crucial components from damage.

- Competitive Weld Neck Flange Price from Weld Neck Flange Suppliers provides cost-effectiveness for your business by offering flanges of high quality at pocket-friendly rates.

Related Products

To ensure comprehensive system protection and efficiency, consider integrating these related products:

- [Gate Valves]: Provides robust shut-off capabilities in high-pressure environments.

- [Globe Valves]: Provides precise throttling and flow regulation, combined with the security connection of weld neck flanges.

- [Strainers]: Protect your weld neck flanges from debris and sediment, expanding their operational life span and keeping flow operational.

Call to Action

“Request a Quote” for bulk pricing, or “Contact Us for More Information” for customized solutions. Our expert team from [Weld Neck Flange Manufacturers in India] is ready to assist you in selecting the ideal flange to meet your specific needs.

Support and Warranty Information

Our Weld Neck Flanges, like the Long Weld Neck Flange and WNRF Flange, come with a broad warranty and complete customer support from reliable Weld Neck Flange Suppliers. We offer instructions on installation, operation aids, and information stipulations for troubleshooting services to keep your flange performing in optimal conditions within its service life.