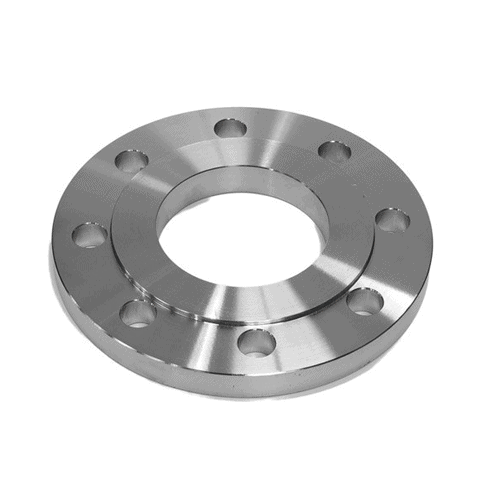

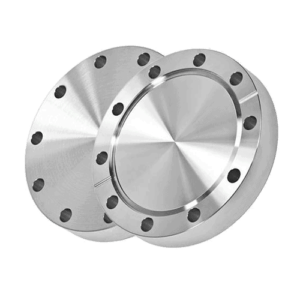

Raised Face Flange

An [Raised Face Flange] (RF Flange) is a very important tool to be working in connection with almost every piping system there is. That rigid and most leak-proof joint it is designed for gives assurance to the attached piping system to remain intact. The flange is heavily welded in oil and gas-related industries and also those related to chemical processing and water treatment, ensuring durability and reliability.

Material Specifications

High-quality raw material, inclusive of stainless steel, carbon steel, and alloy steel, is used in the manufacture of our [Raised Face Flanges]. The materials guarantee great strength, corrosion resistance, and durability. Our [Raised Face Flange] features this special raised face style that increases sealing efficiency, hence even being competent for very high-pressure and high-temperature services.

Technical Specifications

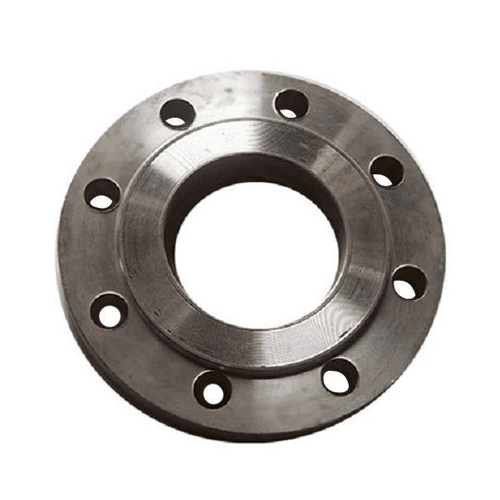

The [Raised Face Flanges] come in sizes between 1/2 inch and 48 inch and can be availed if required for different pipeline requirements. They also have the capacity to withstand pressures of up to 2500 PSI and operate within ranges of about -20°C to 400°C. Elaborate [Raised Face Flange Dimensions] are well laid out so as to match specified system requirements. Common types include the [RF Flange] and [Raised Face Gasket], each designed to provide optimal performance in different operational contexts.

Standards and Compliance

Each [Raised Face Flange] complies with international standards, such as ASTM, ASME, and ISO 9001. Being the best among [Raised Face Flange Manufacturers], we ensure all our products undergo the necessary tests to comply with the standards and assure all our customers of safety, reliability, and performance. The certificate awarded to [Raised Face Flange Suppliers] certifies adherence to quality management and the provision of excellent customer service.

Usage Instructions

Regular maintenance, which includes inspection and cleaning, is encouraged to ensure the best performance and a long duration of the [Raised Face Flange]. General installation should be undertaken subject to the specifications provided by the [Raised Face Flange Manufacturers] to avoid certain mistakes related to common issues like wrong positioning that may be responsible for other functionalities. See the user manual for troubleshooting and more detailed maintenance information, or you can contact our technical support team.

Applications

The [Raised Face Flange] plays a very paramount role as an interface linkage, where applications with no seepage are key to its secure and safe operation. The application extends to the domains of oil and gas pipelines, chemical process industries, and many water treatment plants. The [RF Flange] is the integral face, critical in maintaining the system’s integrity, especially under conditions of high pressure.

Playing a huge part with HVAC systems helps ensure the user gets reliable connections and the pipelines stop leakages. The rugged construction allows for a good amount of durability and reliability in all types of environments. Industrial applications prefer the [Raised Face Gasket] due to added sealing properties that cater to critical applications.

The [Raised Face Flange] is designed to work in high-pressure applications, which assures very secure connections in this type of application. The highly tough mechanism of the raised face flange allows it to wear out, but it is very reliable in harsh and demanding environments. Manufacturers of the [Raised Face Flange] supply a wide range of flanges, including customer-made flanges for a large number of industrial needs. This makes them one of the most preferred suppliers when entering into critical engineering and reliable projects.

Features and Benefits

Features:

- Advanced sealing technology takes place in the [Raised Face Flange] to ensure a tight closure and no leaks occur.

- It is ruggedly built to perform in high-pressure and high-temperature applications.

- Flexible design allows cheap hiring and repair, therefore reducing downtime and labor costs in hiring and repair.

Benefits:

- The high service life with few repairs needed because of the quality of the materials and the robust design.

- As a result, the [Raised Face Flange] ensures leak prevention, improving efficiency, and protecting critical components from damage.

- Competitive [Raised Face Flange Price] from [Raised Face Flange Suppliers], it is able to be cost-effective on the part of businesses whose needs are met by providing them with flanges.

Related Products

To ensure comprehensive system protection and efficiency, consider integrating these related products:

- [Gate Valves]: Has good performance when sealing under high-pressure scenarios.

- [Globe Valves]: Provide accurate throttling and flow control that accommodates the tight, leak-proof capability of the raised face flanges.

- [Strainers]: Protect the flange faces of raised faces from debris and sediment; extend the operational life of the flange faces; and maintain flow efficiency.

Call to Action

Secure your systems with quality [Raised Face Flange]. But just give us a click of “Request a Quote,” and you can get more than one or learn more about our product offerings with “Contact Us for More Information.”. Our experts from [Raised Face Flange Manufacturers] here ensure that you end up getting the perfectly chosen flange for your system.

Support and Warranty Information

Our [Raised Face Flanges] are supplied with full warranty and complete customer support in collaboration with reputable [Raised Face Flange Suppliers]. We accompany our products with installation support, operational support, and troubleshooting services to guarantee that your flange works at its best levels throughout its service life.