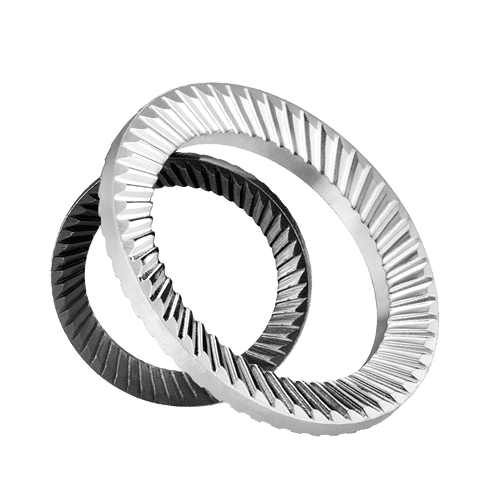

Types of Serrated Washers: Although there are multiple types present as per job need, a few of the regular ones are:

Serrated Disc spring washers: They are conical disc-shaped washers having serration of both sides. They function as to sustain the necessary tension and the available serration helps to avoid loosening. The diameter of disc washers is determined to match the head of the bolt.

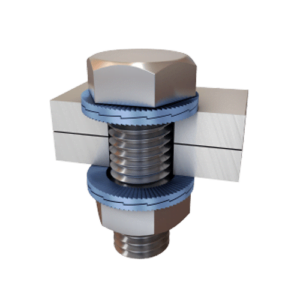

Wedge Lock Washer: Wedge Lock Washers are mainly used to sustain dynamic loads. They are available in pairs glued together. When dynamic stress is applied, the movement is between the internal surface of the pair leading to more clamping strength. The unique feature of a Wedge Lock Washer is the use of tension for locking purpose instead of friction.

Internal Serrated Lock washers: These washers have serration in the form of teeth in the inner side of the washer. Also known as internal tooth washer, the ideal application includes installing with a bolt of smaller head size.

External Serrated Lock Washer: The main difference between internal and external lock washers is the location of serration. It is ideal for the mating part with a large head size. The objective is to cover maximum contact possible with the bolt head.

Working Fundamental

Serrated washer function when fitted very tightly with the nut or bolt. When pressure is applied through tightening, they penetrate the surface and the sharp edges insert into the part to prevent any counter-clock motion of the part and prevent it from loosening.

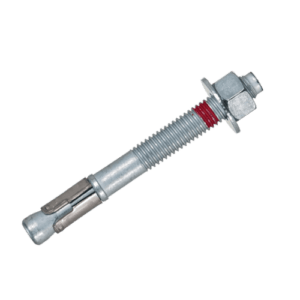

How to use

The first step is to identify the type of washer required for the particular job as they differ from one to one. One of the common steps involved in each case is to tighten the part so that the serrations enter the mating part. They are generally used with another washer and the serrated one goes on the nut side. Some washers like Wedge Lock Washers are reusable, but washers like internal and external tooth can be used only once.