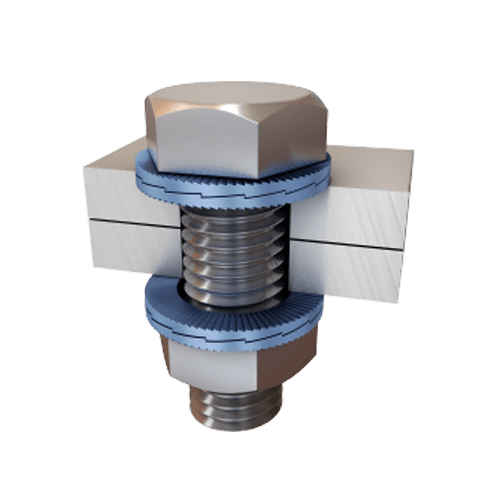

Functioning of Wedge Lock Washer

Tension instead of friction is the principle of working in these washers. They are designed using basic geometry which allows them to form a wedge between pair and serrations on one side, which impregnates into the mating part, i.e. the bolt and the surface to which the bolt is tightened.

Method of application

The alternative locking solutions like Loctite are used as thread sealant for many bolts which have limited applicability as it depends on skills of labour installing it and the area where it is being installed. The installation of wedge lock washer is very simple. It is installed in the same way as a flat washer, just needed to be tightened properly and the serrations on outer surface need to be inserted into the adjacent part.

Benefits of using Nord-Lock washers

- Reliable locking

- Can be easily installed and dismantled

- High resistance to corrosion (various coatings available as per application)

- Lubrication doesn’t affect the locking system

- Can be Reused, unlike other locking systems.

Areas of application

- Mechanical engineering

- Wind energy technology

- Railways

- Bridges and Structructure

- Automobile Industry

Availability

Offered washers are available in Carbon steel and Stainless steel. Can be made available in other material also on special request.