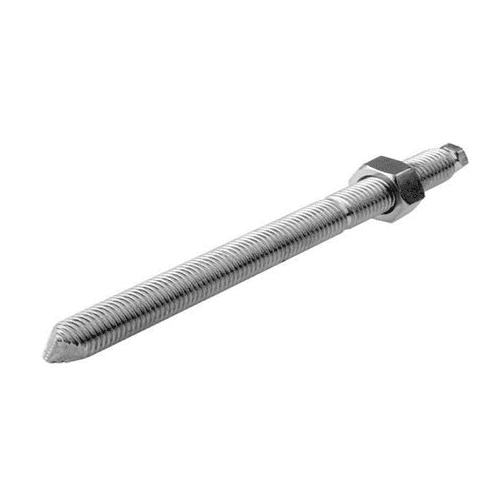

Chemical Anchor

The [Chemical Anchor] is adhesive used to place anchorages in concrete and masonry to hold up structures like concrete, rebar, threaded rods, among others. It provides a strong, tight bind to allow structural integrity in most applications. The same is always essential in construction projects, particularly when it comes to precision and strength, in places.

Material Specifications

The high-quality epoxy resin and hardeners employed in the formulations of our Chemical Anchors ensure a good-quality adhesive bond and, thereby, optimum durability of the adhesive. Especially well known are our Chemical Anchors and Fischer Chemical Anchors. These have been performing extremely well under severe environmental conditions and, hence, establish themselves as a reliable solution to any number of applications.

Technical Specifications

These are available from sizes varying from 300ml cartridges to 1400ml cartridges, generally used to bond anchors with diameters of 8mm to 32mm. [Hiltis Re 500] is one of the popular versions which has great load-bearing capacity. Also, it is resistive against chemicals and weathering. Some of the common details in specification include curing times, load capacities, and temperature resistance.

Standards and Compliance

Every one of our [Chemical Anchors] conforms to ASTM and EN standards, so it may meet international ones. Being among the major [Chemical Anchor Suppliers], we assure our products to undergo rigorous testing processes before meeting the above-mentioned standards and assure our customer safety, reliability, and performance. Assured quality management systems and promised excellence in customer service are hallmarks of [Chemical Anchor Manufacturers].

Usage Instructions

Be sure to apply per the application instructions to achieve the utmost performance and life out of the [Chemical Anchor]. Clean the surface by removing dirt, grease, and loose particles. Put the chemical in the hole from drilling with the adhesive and make sure the anchor is fully encapsulated. For detailed instructions, refer to the user manual or contact our technical support team.

Applications

A chemical anchor, on the other hand, plays an important role in a structural project that calls for the joining of heavy and strong connections. It is widely applied in anchoring rebar into concrete, anchoring threads in masonry, and installations of heavy machinery. One can’t ignore the importance of the Chemical Anchor variant, especially in high-load and critical structure applications where safety is of the essence.

Formulated especially for marine and industrial exposure, the [Chemical Anchor] ensures appropriate chemical and water resistance. Its tough formulation ensures durability and reliability in various conditions. The versatility of the [chemical anchor bolt] in securing the heaviest of loads into concrete breeds a love for it.

The [Chemical Anchor] is specifically designed to bond rebar and concrete safely and securely in a high-stress environment. Its robust mechanism behind produces all durability and reliability features, just right for hard and strenuous conditions. [Chemical Anchor Manufacturers] make chemical anchors for literally every need, including customized solutions to meet specific industrial requirements. This makes them preferable suppliers for projects that have some sort of an engineering precision demand on reliability.

Features and Benefits

Features:

- The highly developed technology of the applied epoxy resin in the [Chemical Anchor] provides the highest level of bond strength.

- The Chemical Anchor is a very capable device that has consideration for use with critical structural applications.

- Its flexible design makes the [Chemical Anchor] easy to apply, curing quickly, which in turn reduces downtime and labor costs.

Benefits:

- A high service life and low maintenance requirement due to the sustainable formulation and design.

- The effectiveness of a chemical anchor is really high owing to its strong bonding property and parameters that can improve structural reliability and safety.

- With quality anchoring solutions provided at very economic rates, [chemical anchor suppliers] offer cost-effectiveness to businesses through competitive [chemical anchor price].

Related Products

Total holistic system protection and optimization by adding the following allied products:

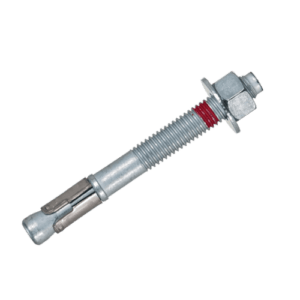

- [Mechanical Anchors]: Strong anchoring capacities that provide for many forms of construction.

- [Chemical Fasteners]: Correct, strong, and compatible joints reproduced with the proper essence of the bonding capacity of the chemical anchoring.

- [Anchor Fastening Systems]: Such efforts secure anchoring that is concrete and masonry structures safe and productive, resulting in extended operational service life and the conservation of structural integrity.

Call to Action

Request for Quotation for bulk prices and click on contact us for information and inquiries on tailored solutions. Our team from the chemical anchor manufacturers can advise you about the most compatible chemical anchor for your needs.

Support and Warranty Information

Our range of [Chemical Anchors], such as the [ Chemical Anchor] or [Fischer Chemical Anchor], is covered by the most complete warranty and all-round customer support from any of our competitors as reputable [Chemical Anchor Suppliers]. Our aftercare services are available for offering assistance in installation guidance, operational support, and all troubleshooting services so that the chemical anchor continuously performs with standards during its entire service lifetime.

Should I go for chemical anchoring for my Task?

The chemical anchoring process involves inserting a resin in the hole before inserting the anchor. Other forms of anchoring do not have this option. Other anchoring processes have to pay close attention to hole diameter and be accurate about hole dimension, if somehow there is no precision in the process the anchor would not be able to provide requisite strength. At times without skilled professionals or little less precise workers, this process becomes tedious and futile.

Chemical anchor manufacturer considers all these issues, and provides you with a more reliable product, gives a better load capacity, and is easy to work with. Some engineers prefer chemical anchors over others is due to the ease of installing process and the amount of load these anchors can hold. Chemical anchoring should opt if there are requirements for superior load bearing and you want the installation to be hassle-free. If there are further specific issues concerning you, one can always confirm with engineers or our support team to help you make the right selection.

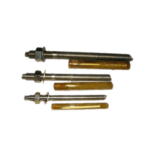

How Does Chemical anchoring exactly work?

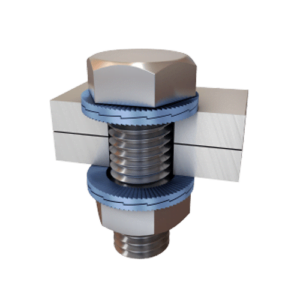

Chemical anchoring as the name suggests usually involves drilling a hole and inserting chemical resin in it. The resin fills the irregularities of the hole and any dimension issue occurred while drilling. Once the resin is filled the chemical anchor fastener and the chemical anchor bolt are inserted. The resin assures 100% adhesion and is waterproof. This is the reason that chemical anchoring provides increased load capacity. There is practically unlimited embedment depth for the rods inserted. The length and diameter of the rod can be increased as per requirement and there would be no issue for the hole already made. There is little difference to the working of the anchor relating to base material be it weak or with strength.

The basic difference between chemical anchoring and other anchoring is the use of the additional chemical resin used after drilling the hole. This is unlikely practice with other forms of anchoring.

Pros and Cons of Chemical Anchoring

In general, there are many pros and cons discussed in chemical anchors. There are some myths and facts to this aspect. Here we have presented the exact pros and cons of chemical anchors. We have discussed the practical scientific aspects of chemical anchoring that would help you make a wise decision regarding anchoring choice.

Pros:

- Provides a better load capacity.

- Can be used in poorly drilled holes.

- Can be used on weaker bases as well.

- The distance between two anchors can be reduced with chemical anchoring.

- The diameter and length of embedment can be increased with ease.

- Engineers’ choice at critical fixings.

- Reliable load strength capacity.

Cons:

- A skilled person is required to complete the anchoring process.

- Chemical anchors suppliers generally fail to impart accurate information about the utility.

- The cost of these anchors maybe a little more than other forms.

- Poor hole cleaning might affect the working of the anchor, thus before inserting resin capsule proper hole cleaning becomes vital.

Chemical Anchors or Mechanical Anchors?

Chemical anchors are often compared with mechanical anchors. These are the two types of anchors that are often discussed together. Though the functioning of each of them is different and they both are apt for different conditions. As we have discussed above chemical anchors use a resin in the fixing process. But, with mechanical anchors, the installation process is a bit different. Mechanical anchors such as Dynabolt, wedge anchors, and others expand upon tightening.

Mechanical anchors are also preferred for certain situations.They do not cover the irregularities left during drilling of the holes. Mechanical anchors are not suitable for places where the surface is unable to provide sufficient grips. As there are chances the anchor would leave the surface and get dismantled on load-bearing. These are some of the drawbacks initially of mechanical anchors over chemical ones. This is the primary reason chemical anchors have become engineers’ favorite over the years. It does not mean that mechanical anchors are the wrong choice, but they are to be selected when the surface situations permit their use. Based on the available information before installation if you can make a choice, it would be good. But, if somehow it becomes difficult for you to decide, it would be wise to consult an expert for your anchoring needs.

Good Place to Buy Chemical Anchors

There are many chemical anchor suppliers in the market that have a variety of options. But, the drawback with most of these is they do not have sufficient information on the utility of the chemical anchors. Induskart had brought in evolution in this aspect. Induskart has done sufficient research in the field and has collected scientifically researched information on each of the products sold on its platform. Induskart believes that a customer should be well-informed while making any critical choices for their industry.

Induskart is an authorized supplier to many Chemical Anchors brands such as Mungo, Fischer, and many more. There are a variety of Chemical anchor brands available on the Induskart platform.

Induskart has also launched premium quality chemical anchors with the brand name ASAGRO, these are premium quality chemical anchors approved on international standards. With Induskart it is no more difficult to get genuine and good quality chemical anchors in bulk or small quantity. Place your order easily online and receive your order at your desired destination without any hassle.

One can also find chemical anchors bolts for concrete, chemical anchor resins on the website. These products are supplied by Induskart in the remote areas of India hassle-free. Shop online for good quality, genuine chemical anchors on Induskart.