Understanding the Dynamics of the Global Industrial Equipment Market

In the growing world of technology, there is an era witness to unending technological progress and achievement. The global industrial equipment market is a prime example of such achievements. The…

Crafting an Effective Industrial Waste Management Plan

While managing industrial waste has become a significant social topic, did you know that unmanaged industrial waste is enough to cause industrial pollution the same as that caused by millions…

How to Implement Lean Manufacturing Techniques in Your Factory

In today’s world where efficiency and sustainability are considered a necessity, lean manufacturing stands out as one of the most important strategies for factories globally. Lean manufacturing has a set…

Tutorial on Using Advanced Diagnostics for Industrial Equipment Troubleshooting

The maintenance world is fast-paced, but there is one area many professionals miss which is incredibly important—advanced diagnostics. This goes beyond just fixing what is broken; it is critical to…

Maintaining Industrial Machinery: Best Practices and Routine Check-ups

From manufacturing to construction, industrial machinery is a familiar sight across every sector of business, serving as their backbone. Equipment is maintained at peak performance through routine maintenance, which, when…

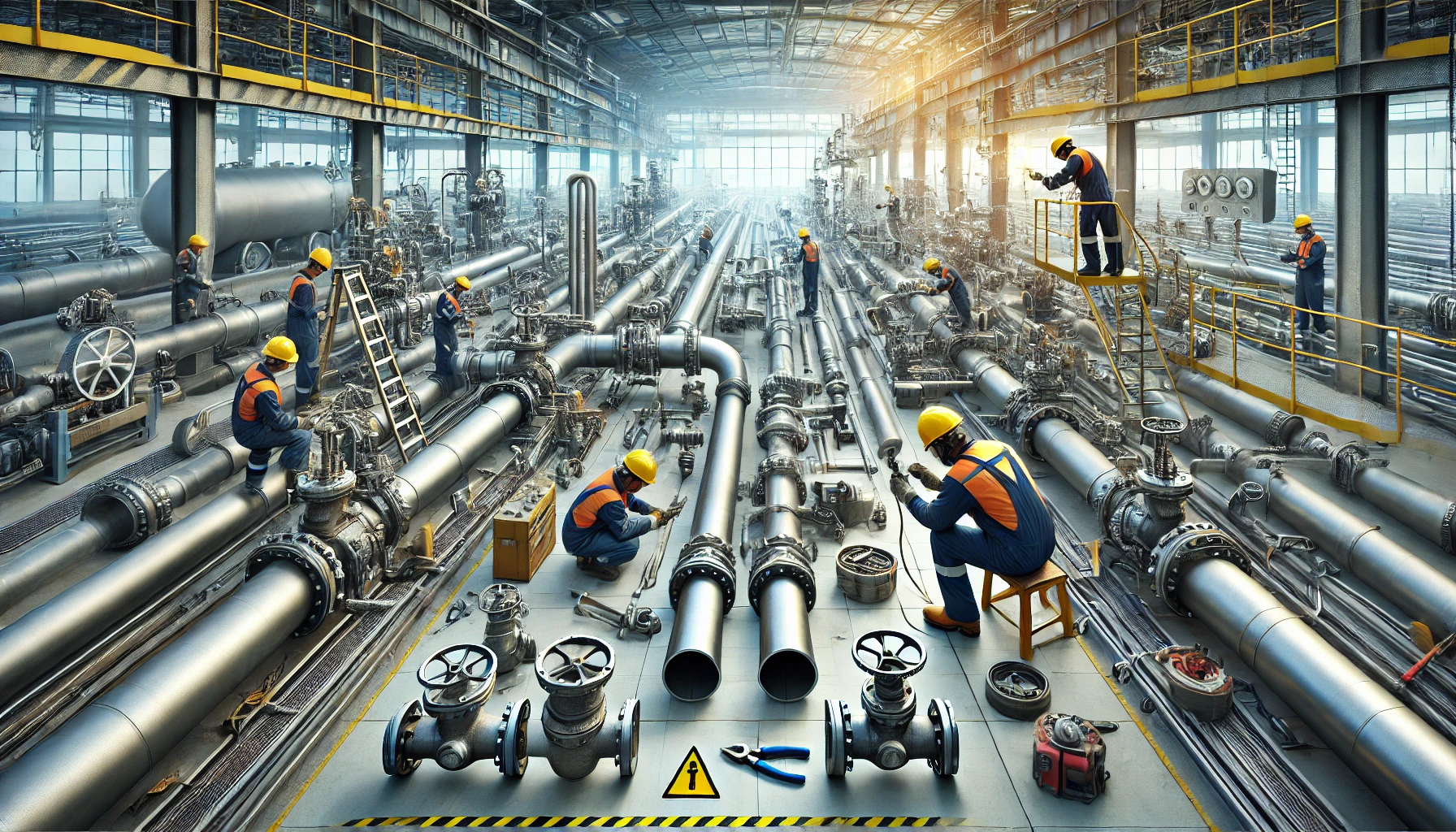

Step-by-Step Guide to Installing High-Pressure Industrial Piping Systems

The high-pressure piping systems are diligently working in the background and make sure that multiple processes are seamlessly executed during industrial work. These systems help in operating machines and fluids…

AI vs. Manual Inspection in Quality Control: A Comparative Study

AI technology is revolutionising the industrial manufacturing sector, with quality control emerging as one of its key components. Unlike other functions which can operate with reduced oversight, quality control remains…

Evaluating Different Industrial Waste Management Techniques

In the modern era, waste has to be taken care of in a systemized way and it goes beyond legal restrictions. It has to ensure that it is part of…

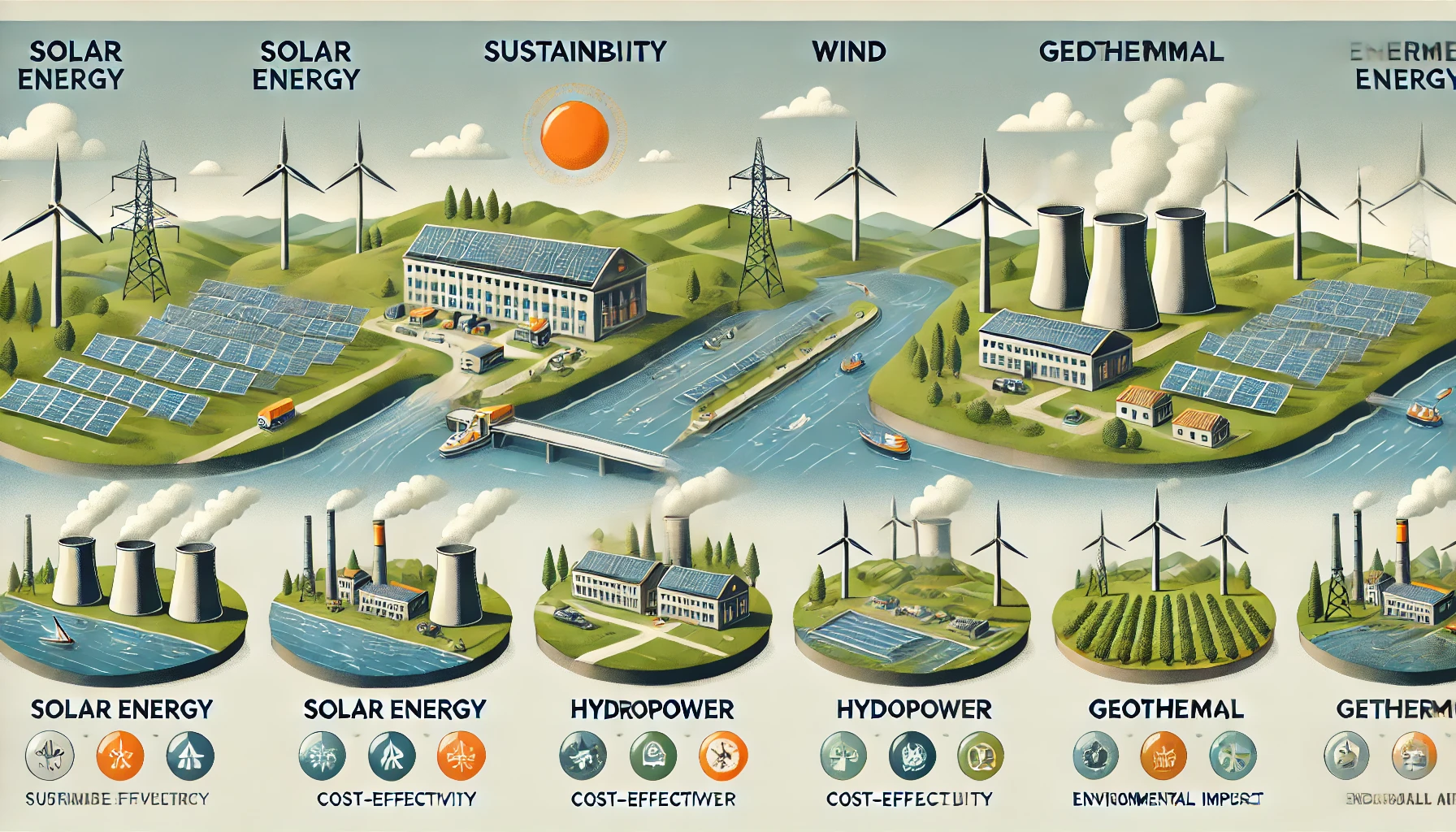

Comparing Renewable Energy Sources for Industrial Applications

Have we taken into account the role of renewable energy in changing the industrial landscape of the economy as one of the most important factors in climate change mitigation?” Today,…

3D Printing vs. Injection Molding: An In-Depth Comparison for Manufacturers

Is 3D printing the future of manufacturing? Labor-intensive activities are replaced by robotics. Oh yes, it is cut and dry when it comes to considering 3D printing additive manufacturing vs…