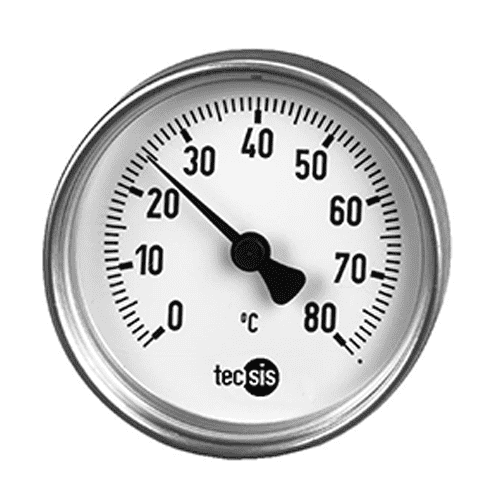

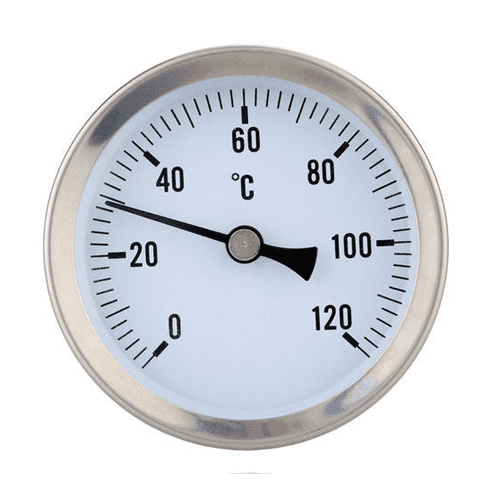

Precision Temperature Gauge for Accurate Temperature Monitoring

This device indicates the temperature of the item under observation. It is an important tool for showing precise temperature readings required to keep various industrial processes at their optimum operational conditions. The display could either be an analog dial, an analog range or a digital readout which gives room for flexibility depending on what the user wants and where it will be used.

Material Specifications

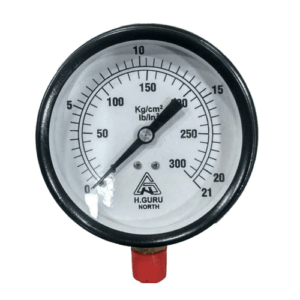

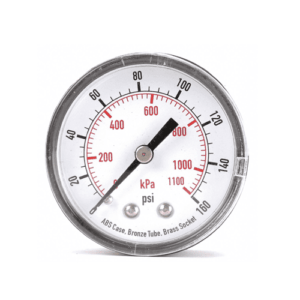

The materials used in making our gauges are of high quality such as stainless steel and brass that are resistant to rusting thereby increasing their lifespan. Such strong components enable them withstand tough environmental conditions often found in industries thus they always perform reliably even if subjected to extreme situation like very high temperatures or pressure as in case of [High Temperature Steam Pressure Gauge] designed specifically for steam applications where accurate reading must be guaranteed even when exposed to severe heat.

Technical Specifications

These devices come in different sizes ranging from 2 – 20 inches diameter; this implies that there is no limit regarding how large or small one’s needs may be since they have all sizes available. They also possess high accuracy levels having tolerances within +/- 1% Full Scale Deflection (FSD). In addition, there are varied connection types including NPT and BSPT coupled with electromechanical / solid state switch types while displays can either be analogue or digital depending on what someone prefers using or where its application demands so.

Standards Compliance & Quality Assurance Measures

All products offered by us strictly adhere to international standards i.e., ASTM ISO9001 among others being top manufacturers , we take pride in ensuring that our outputs meet very strict quality control tests which guarantees safety effective performance under any given circumstances within diverse industries worldwide .

Usage Instructions

Regular maintenance as well calibration should never miss out when handling these instruments if one desires better results over time bearing mind their durability . Manufacturers’ instructions must always followed during installation process failure which might lead common errors like wrong positioning leading to malfunctioning thus affecting its functions. For more information on usage tips troubleshooting kindly refer user manual or contact technical support team .

Applications

These are used to control heat levels in various sectors where they cannot be avoided this includes; HVAC systems , industrial boilers and chemical processing among others. [High Temperature Steam Pressure Gauge] is ideal for steam systems because it ensures accurate readings under high pressure conditions which could compromise safety if not taken into account ; food processing pharmaceuticals as well other areas that require strict regulation of temperatures.

Features and Benefits

Features:

Highly Accurate– Measures with precision up to +/- 1% FSD.

Versatile Displays – Available in both analogue and digital formats depending on what you prefer or where it will be used

Strong Construction Material – Made from durable stuffs capable of withstanding harsh surroundings during operation

Wide Range Of Sizes – Comes in different diameters ranging from two inches all through twenty inches hence fitting in any application need .

Demand for Action

Develop your ability to monitor temperature with our precise [Temperature Gauges]. Press ‘Add to Cart’ for immediate purchase, ‘Request a Quote’ for bulk pricing, or ‘Contact Us for More Information’ for tailor-made solutions. Our expert team from [Temperature Gauge Manufacturers] is ready to help you choose the best gauge that suits your needs.

Support and Warranty Information

Our [Temperature Gauges], inclusive of the [High Temperature Steam Pressure Gauge], are supported by a wide-ranging warranty together with complete customer support from reputable [Temperature Gauge Manufacturers In India]. We offer installation guidance, operational support as well as troubleshooting services aimed at ensuring maximum performance of your gauge throughout its lifespan.